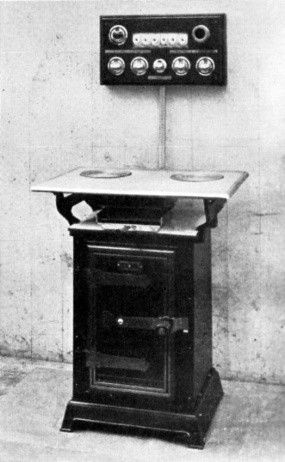

Carron Company was always innovative and adopted the use of electricity at an early date, generating its own power from coal from its own collieries. By 1896 it was also manufacturing components for those producing machinery for the generation of electricity (Falkirk Herald 4 January 1896, 6). Electrical goods such as cookers, fires, irons, and so on were being churned out of Carron long before most other companies took up their manufacture. In 1910 it put domestic electric cookers on the market.

The Carron Company Book of 1938 gives us a good idea of the state of play at that date:

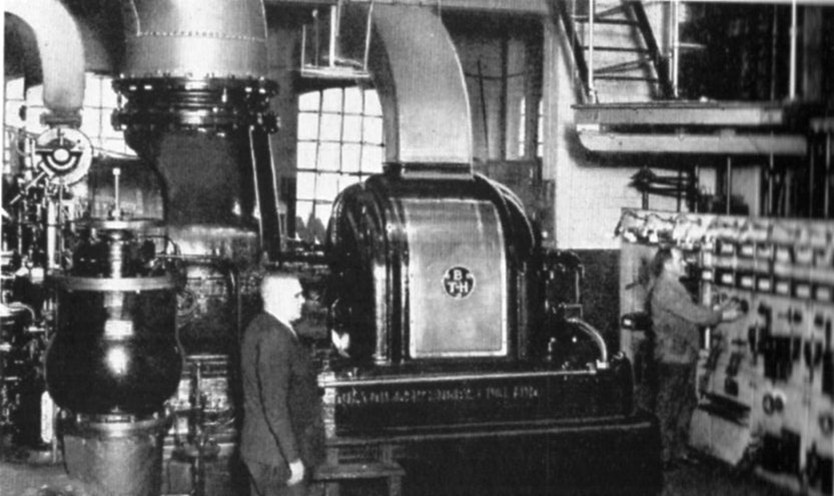

The electrical plant at Carron Works is laid out along the lines of the latest modern practice. The steam raising plant for the power station consists of a battery of water tube and Lancashire boilers with superheaters and economisers which are fired by waste gases from the blast furnaces. The main power station equipment consists of four high-pressure turbo alternators, having a total output of 3250kw AC at 500 volts pressure, which is supplied to sub-stations over miles of overhead lines at a pressure of 3,300 volts over a large area to the works and collieries owned by the Company, the pressure being stepped down to 500 volts or converted to DC power by means of rotary convertors. Condensers at the various sub-stations maintain the power factor correction at 0.95.

There has recently been installed at Bannockburn Colliery one 1,000kw mixed pressure generator and one 500kw inverted type rotary converter (the rotary converter supplying power at 3,300 volts for the heavy pumping duty underground). This machine can supply either AC or DC power.

There is also at present being installed in this power station, one 750kw mixed pressure turbo alternator as a stand-by set to the existing machines. The whole of this plant is laid down on the most modern electrical practice, having earth leakage, protection, field suppression and all switchgear electrically inter-locked so as to insure the maximum protection to plant and operators. The power consumption of the works and collieries amounts to 16,000,000 units per annum, almost entirely supplied from the Company’s own power stations. This power consumption is greater than that of many of the large towns in this country.” (Carron Co 1938, 60-61).

Up to and during the Second World War four shell factories were created within the Carron complex. The electricity supplies for these were deliberately varied so that they would not all be put out of action by enemy bombing. Only Shell Factory No. 3 was supplied from the Works’ Power Station. Nos. 1, 2 and 4 got their power from the Falkirk Burgh Power Station. In 1942 a steel foundry was started up to contribute to the war effort. It had Duplex electric furnaces for the manufacture of tank tracks.

By the early 1960s the old coal-fired blast furnaces at Carron Works had become inefficient and so estimates were obtained for the installation of an electric arc furnace. This, together with charging and casting facilities was put at £200,000, whereas re-lining No. 7 blast furnace alone would cost £20,000 and take six months. For some time the Work’s own power station had been giving serious cause for concern. Only one generator was in service and there was no standby machinery. For the first time it was decided to take an electricity supply from the National Grid. Reports showed that it would take 18 months or so for the South of Scotland Electricity Board to install the necessary cables and transformers up to the works at a cost of £50,000 to be paid by it, and £30,000 for alterations to the cables and transformers within the works, the cost of which was to be borne by Carron Company. This scheme was proceeded with and at the end of October 1961 the Carron Company’s power station closed (Watters 2010, 244-5)