for Falkirk District Industries

As well as the large electricity generating stations erected by local corporations and private companies to provide power to the general public in urban areas, there were a large number of businesses which had their own supply. This was partly due to the cost benefits of utilising spare capacity on their steam engines, and partly due to the security it gave them over the supply. However, it was also due to the relative remoteness of some of the works prior to the establishment of a supply grid. Indeed, many were set up before the other power stations came on line.

At the forefront of the adoption of electricity were the coal mines, where naked flames were a potential hazard. Locally, several pits had electricity in the early 1890s (see The Early Days of Electricity in Falkirk). Electricity was particularly attractive to the coal industry because of a combination of factors, firstly they had a ready (and cheap) source of fuel and one which did not have to be transported far and secondly, they had a high power demand for hauling their product to the surface and lighting underground. This combination of factors made it worthwhile for many colliers to buy, install and run their own generation equipment. For the mines in the Falkirk area there is limited documentation, but the following provides a useful starting point:

| LOCATION | DATE | DETAILS |

|---|---|---|

| Woodyett | 1894 | Electric safety lamps introduced. |

| Redding | 1948 | James Nimmo & Co, Nationalisation Report states DC electricity generation at colliery. |

| Carriden | 1948 | The colliery used to convert its coal in a boiler house into steam for generating its own electricity. By the time of the 1948 Nationalisation Report it was bought in. |

| Standburn No 6 | 1926 | From description of Standburn Miners’ Welfare Institution which was supplied by the pit. |

| Herbertshire | 1948 | 1948 Nationalisation report states electricity generated at colliery. |

| Craigend Colliery | 1908 | Power house generating electricity to power the winding gear, the lighting, the fans ventilating the underground passages, drainage pumps and conveyor belts in the coal sorting and washing plants. A 1908 photograph shows the power house. |

| Furnaceyard Pit – Kinneil Coal Co | Fire in 1935. |

The 1938 souvenir book on Carron Company provides us with the following information on the usage of electricity in its mines at that date:

“Electricity is widely used and has made vast differenced to the rate of production , to the quality of the product, and to the safety of the miners. Manual labour has been largely superseded by machinery. The coal is cut by electrically-worked machines, which make for greatly increased output and for the working of coal which was previously not profitable to work. And the hauling and conveying of coal along the roadways is now done by electrically-operated haulage gears, by belts and jigger-type conveyors, thus dispensing with the need for pit ponies and for human labour for those purposes. The pumping of water from the Company’s mines is carried out entirely by electric pumps, which have revolutionised the pumping system; for these pumps can deal with a very much greater volume of water than could the old pumps worked by steam or compressed air. So, too, is the ventilating system carried out by electric fans. As a result, the ventilating system is many times improved, coal can be worked at much deeper levels, yet the air in workings two miles removed from the shaft is cleaner and purer than that of a large city on a foggy day. Again, through the use of electricity, coal can be raised in greater quantity, from greater depths and at higher speeds than was possible in former days. Very efficient balanced winders are used for this purpose, and coal can be raised from the shaft at speeds of up to forty miles per hour.” (Carron Co 1938, 29).

Electricity was also used at the docks in Grangemouth and Bo’ness to handle the exports of coal as well as the imports of other raw materials. Grangemouth, operated by the Caledonian Railway Company, was the first port in Scotland to be lit by electricity in 1884. The Dock and Harbour Commissioners at Bo’ness suggested the adoption of this system in 1890 but it was 1898 before it purchased old electrical plant from Edinburgh Free Library. The plant consisted of two engines, two boilers, and two dynamos. It was installed by the Brush Company.

To work the dock at Bridgeness where coal was exported from the Carriden coalfield, Henry Cadell designed a compound condensing beam engine of a peculiar pattern with a vertical and a horizontal cylinder. It worked well for about 50 years, but had the drawback of taking steam down the downcast pit (No.6), which injured the ventilation and wasted much steam. It ceased and was replaced by modern electrical haulage in February 1931.

Power stations were to be found all over, particularly in heavy industries such as brickworks, chemical works, distilleries, iron foundries, paper mills, shipping ports, and woodyards. Below, the following will be examined in more detail:

| Herbertshire Paper Mill, Denny – John Collins | 1887 | Electric lighting installed |

| Stoneywood Paper Mill – John Collins | 1887 | Electric lighting installed |

| Bo’ness Distillery – James Calder & Co | 1907 | Power plant |

| Grangemouth Dockyard – Greenock & Grangemouth Dockyard Co | 1917 | Power station |

| Furnaceyard Pit – Kinneil Coal Co | Fire 1935 | |

| Brownlie & Co, Grangemouth | Extension to power station |

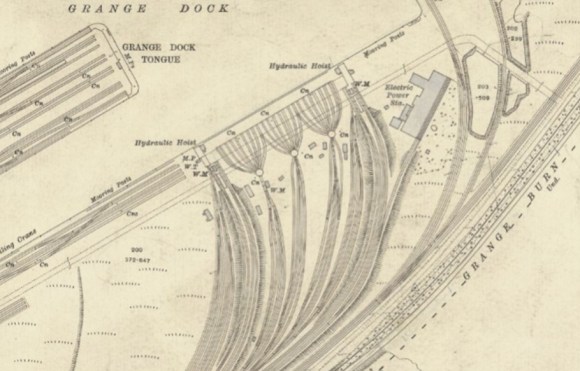

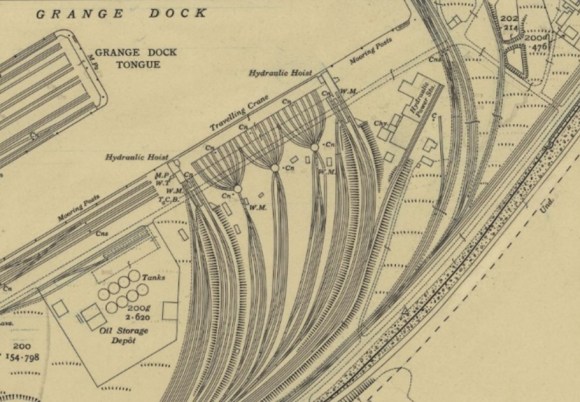

At the end of the 19th century a different power source made an appearance – hydraulic power using high pressure water produced by steam driven pumps and stored in accumulators was developed to drive machinery. Some cities, including Glasgow, even had dedicated hydraulic power stations and a public distribution of high-pressure water using ring mains. As always, the Falkirk area was at the cutting edge of technology and the Grangemouth Docks made use of this form of power with not one but two of its own dedicated hydraulic power stations. The first one was built in the 1890s and is thought to have also housed the electricity generation equipment; the later one was built as part of the Grange Dock expansion. Both were used to operate coal lifts, cranes, capstans, swing bridges and dock gates. The earliest one was swept away in one of the many developments of the docks over the years. Even the Ordnance Survey got confused and it is mislabelled as an Electric Power Station in 1915 but at least they had corrected it by 1943!

Bibliography

| Carron Co. | 1938 | Carron Company: from the reign of George II to the reign of George VI 1759-1938. |

| Veitch, J. (ed) | 1948 | Stirlingshire Industrial Guide. |

| Watters, B. | 2010 | Carron: Where Iron Runs like Water. |

| Waugh, J. | 1981 | The Vale of Bonny |