It was 1842 before the Borrowstounness Coal Gas Light Company was established and May 1844 when it first produced gas. Street lighting was only turned on in 1846. The lamps were erected by public subscription and were only lit from September to April, except on moonlight nights. Land was acquired on the south side of the main road at the Links and the gas producing plant and a small gasometer were erected. John Anderson was the first chairman, Henry Rymer treasurer, and James Dunlop clerk. Other directors were Andrew Vannan (distiller), Wm Donaldson, Daniel M’Intosh, Thomas Oliphant, John Cuddeford, William Miller (saddler) and Andrew Gardner (innkeeper) – all well-known businessmen in the town. One of the big investors was the Bo’ness Landsmen’s Society. Anderson also had a large number of shares which he eventually placed in the hands of the Trust that bore his name. The price of gas to begin with was 7s l0d per 1000 cubic feet. Owing to this high price the gas was not used much in houses or workshops, and the gas works did not produce a profit for the first few years. The price was gradually reduced, and a dividend came to be paid.

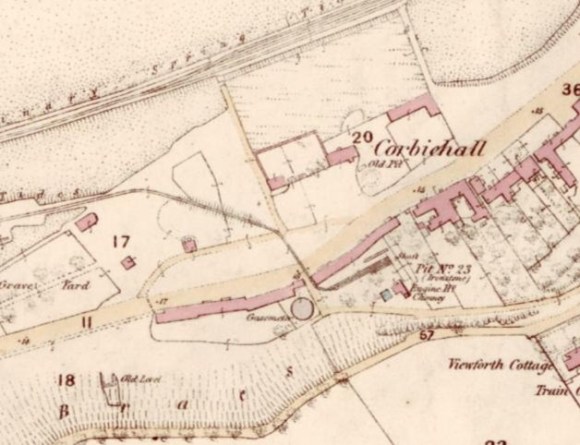

A gas-holder was erected at Corbiehall in 1855, and this addition brought the capital of the company up to £2,400. It is mentioned in the description in the Ordnance Survey Name Book the following year :

“a gas work having two gasometers, the one at the west end of the town contains 17,000 cubic feet, and that at the work contains 7,200 feet.”

The western, or Corbiehall, gasometer helped to supply Kinneil to the west, and in the east the mains soon reached Carriden Brae. The Bo’ness Gas Light Company kept up-to-date with technical developments of the production of coal gas and adopted the best and most economical of these. By the 1880s the works were running well and in 1884 a house was built for the manager, who was granted free accommodation on top of his salary, with free use of the gas therein. At the same time a board room was erected for the directors and from then on the annual general meetings were held there. Customers were not granted the free usage of gas and those in arrears of payment after the closing of the accounts on 31st May each year were cut off.

For Queen Victoria’s 1888 Jubilee the Directors of the Bo’ness Gas-Light Company erected, at their expense, a large and powerful Wenham gas lamp on the top of the Jubilee Fountain in Market Street, and presented it to the Commissioners of the Town. Their co-operation with the Town Council also extended to helping with a problem with the burgh’s sewers. The build-up of foul gas in the underground network of sewerage pipes led to disgusting smells being emitted from the street grids, especially in the summer months. The plan adopted for drawing off the foul gas was to insert a connecting pipe into the chimney stalk of the gasworks. The draught drew the foul gas out of the sewers, though it took a few initial weeks for it to dissipate the build-up. The resulting smell at the gas works cannot have been particularly noticeable as the property immediately to its east was the Burgh drying green and there were no complaints about smelly laundry or soot! The tall square chimney stalk had been erected in 1882/3. Every few years the contract to supply gas to the Town Council for the street lights was renewed. Although the Bo’ness Gas Light Company had a monopoly it does not appear to have exploited it. In 1889, for example, it offered to supply gas for the public lamps for 218 nights at the rate of 15s 6d each lamp burning from dusk to eleven o’clock on week nights, and twelve on Saturdays, and 28s for those kept burning all night, as against 17s for the ordinary lamps the previous year, and 30s 6d for the all-night ones. It also offered to renew the contract for the maintenance of the existing lamps for five years at £20 a year. In addition, it agreed to dispense with the charge of 4s for the erection of new lamps, provided that not more than 16 new lamps were put up in any year.

By 1887 some of the old mains were in need of replacement and the Council granted the Gas Company permission to dig up the road between Bo’ness and Kinneil. The burgh surveyor kept an eye on the work and reported that it had been carefully executed, and the cost of restoring the part of the road opened was defrayed by the company. Unfortunately, although the work had been executed according to the standards of the day, the tight curve in the road in front of the chemical works of Thomas Ovens & Sons meant that the joints were insufficiently protected from the vibrations of the heavy traffic and gas escaped. In November 1889 a sudden loss of gas from the system was noted at the gas works and the following day the leak was traced to the road in front of Ovens’ Works. It was whilst the gasmen were opening up the road that an explosion occurred in the nearby foreman’s residence. The house was engulfed in flame and the wall of the adjoining laboratory was demolished. Amazingly, the gas flame did not set fire to the timbers of the house and the people inside were not seriously injured. Thomas Ovens & Sons sued the Gas Company for £258 9s 5d, and won, after an appeal.

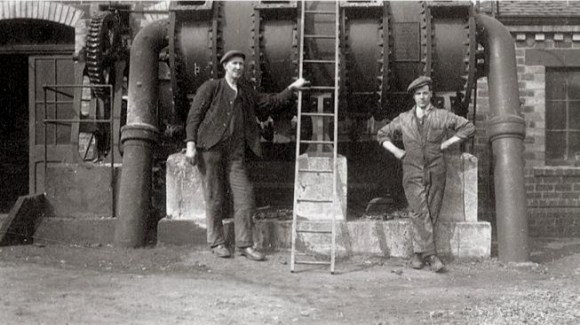

To meet the increasing demand, three additional condensers and a scrubber washer were added to the works in 1889 at a cost of £300. The Corbiehall gas-holder was no longer in use in 1895 and was demolished shortly thereafter.

| YEAR | PRICE per 1000 ft | GAS PRODUCED (cubic ft) |

|---|---|---|

| 1881 | 5s | |

| 1882 | 4s 7d | |

| 1884 | 4s 2d | |

| 1888 | Just over 10 million | |

| 1889 | 3s 11½d | Nearly 11 million |

| 1909 | 3s 4d | Up 1.5 million on previous year |

| 1913 | 32.2 million | |

| 1914 | 2s 11d | Up 2.46 million |

| 1915 | 3s 9d | |

| 1916 | Up 2.4 to 37 million | |

| 1917 | 35.9 million | |

| 1922 | 5s 4d | Up 2 million |

| 1923 | 4s 11d | |

| 1927 | 5s 5d (5s 11d) | |

| 1928 | 4s 2d | |

| 1946 | Up 6 million to 70.9 million |

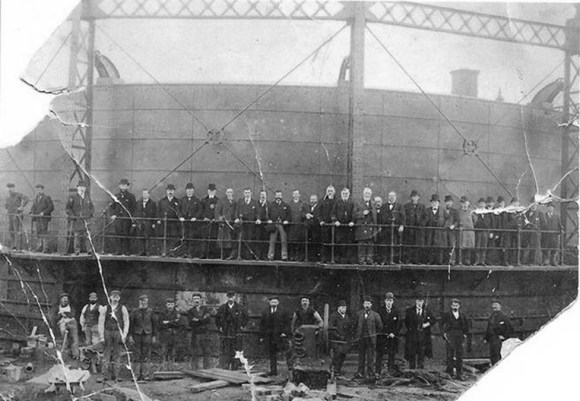

At the commencement of 1897 the Bo’ness Gas Light Company (Limited) was registered as a joint stock company with its registered office at 14 Links Road with a capital of £25,000 in £5 shares. It acquired the undertaking of the Borrowstounness Coal Gas Light Company. A new gas holder and other plant were immediately added to the works and inaugurated in November that year. The new gasometer stood on the opposite side of the road and had a holding capacity of 100,000 cubic feet, and cost about £7,000. It was of the telescopic variety which meant that it rose and fell according to the amount of gas it contained. The town used around 90,000 cubic feet of gas a day. The work on the new plant was undertaken by R & J Dempster of Manchester.

Many towns in Britain had either built their own gasworks or acquired those set up by private businesses. Gas was now seen as a utility in much the same way as water and so Bo’ness Town Council investigated the possibility of buying the Bo’ness Gasworks. For several months in 1900 and 1901 meetings were held and in March the directors of the Bo’ness Gas Light Company (Ltd) intimated that they would recommend a price of £35,000 to its shareholders – but the offer never came forward. The local newspaper was not surprised

“No one in Bo’ness is treating seriously the proposal by Mr Calder, and countenanced by the Town Council, to purchase the gas works. The preliminaries that are being gone on with is providing excellent sport for some of the Councillors” (Linlithgow Gazette 15 March 1901, 4).

In any case, there was no need for the acquisition, the gas company had been providing all the facilities that a municipal works would have and was one of the cheapest in Scotland.

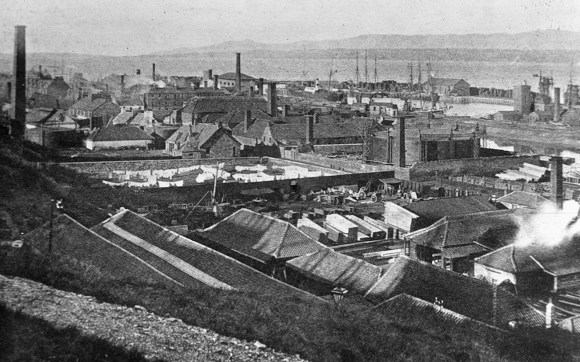

Part of the reason for the failure of the Town Council to continue its interest in the gasworks was that its attention turned to the introduction of electric lighting. The Bo’ness Electric Power Station was opened in May 1905. At first it looked like electricity would replace gas. However, side by side with the electricity works the gas works prospered. The amount of gas consumed during 1909 exceeded the consumption of any previous year in the history of the company. The clear inference was that there was room for both, especially as the demand for gas cookers and heaters increased.

There were then still 57 gas lamps in the burgh, and the Town Council accepted an offer by the Gas Company to give a trial to incandescent gas burners fitted in air-tight lanterns. It was estimated that the candle power would thus increase fivefold – the industry was fighting back with innovations of its own. By 1913 there was an increase in gas sales of 25% since the start up of the electricity works. The gas main was extended the short distance up the Carriden brae to Muirhouses in 1914.

Despite the rate for ordinary meters being cheaper than slot meters the public favoured the latter as they paid in advance and could control their spending better. In 1911 the number of collections was reduced from four a year to three.

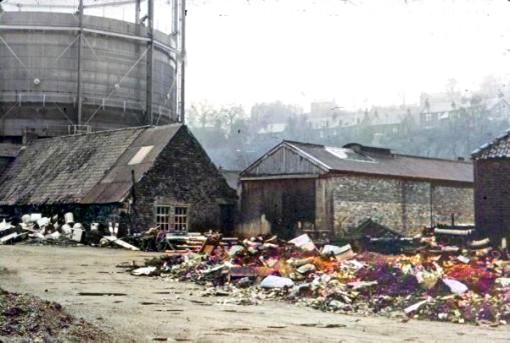

In 1912 a beginning was made to improvements to Links Road and many of the old buildings at the gas works were demolished and a substantial boundary wall erected by the company. It was at this time that a degree of turbulence entered the coal market and 1912 witnessed a sharp rise in prices. This was partly offset by an increase in gas consumption providing a greater economy of scale. The old gas holder in the works was dismantled in 1914 and a shed erected in its place to store purifying material which included lime, though now a new material was also used (Lux) which saved on costs. Arrangements were made for sending the tar and ammonical liquor to the chemical works by tank wagons instead of in casks. Not only was this more convenient but it also made an annual saving of cartage for £40. A pipe led from the works to the tank waggon on the railway.

The old rope-work house to the south of the gas works was demolished and a store erected there capable of holding 400 tons of coal. This was done in order to cope with the intermittent supply and high price of the coal.

| COAL USED (tons) | GAS PER TON OF COAL (cubic ft) | COKE PRODUCED (tons) | TAR & AMMONICAL LIQUOR (gallons) | RESIDUAL % COST of COAL | LEAKAGE % | |

|---|---|---|---|---|---|---|

| 1914 | 3273 | 9909 | 1311 | 155,730 | 66.09 | 13.7 |

| 1916 | 3756 | 9921 | 1446 | 159,367 | 42.25 | |

| 1917 | 3619 | 9907 | 1502 | 160,358 | 50.90 | 10.61 |

| 1922 | 2848 | 946 | 117.829 |

For some time after the First World War the Bo’ness Gas light Company gave consideration to the installation of a water-gas plant, and in 1920 the directors paid visits to several works in order to view the various types of plant in operation. They were favourably impressed with what they saw and in March 1921 placed a contract with Humphreys & Glasgow for plant of 140,000 cubic feet capacity per 24 hours, with all the latest improvements. The plant was operational by the end of October and soon proved its value, leading to a reduction in the price of the gas. Dividends to the shareholders were increased to 8%. The gas network was extended as new housing schemes were built in the town. Marchlands Avenue was connected in 1922.

| ORDINARY METERS | SLOT METERS | COOKERS | GAS RINGS | GAS FIRES | GAS BOILERS | RADIATORS etc. | GAS ENGINES | |

|---|---|---|---|---|---|---|---|---|

| 1914 | -19 | 60 | 31 | 109 | 18 | 4 | – | 1 |

| 1916 | -10 | 26 | 29 | 78 | 23 | 3 + 1 bath heater | 2 | 3 gas furnaces |

| 1917 | -11 | 29 | – | 66 | 12 | 3 | 4 | 4 gas furnaces + 1 core drying oven |

| 1922 | 34 | 72 | 7 | 1 | 24 range-plates; 6 gas irons |

For some time the Bo’ness Gas Light Company had run a showroom at 41 South Street. Here gas appliances were available for hire and included cookers, fires, radiators, geysers, boilers and so on.

In 1932 the Bo’ness works were again brought up to date with the installation of a carburetted water gas plant at a cost of around £2,000. The plant consisted of three vessels – a generator in which gas was made, a carburettor into which oil was sprayed, and a super-heater, in which the oil-gas was fixed. The addition of oil meant that the calorific value of the gas could be adjusted to whatever was required. The plant was capable of producing 10,000 cubic feet of gas per hour.

The running of gas works was improved throughout Britain with technical innovations, and in 1931 a “dri-gas” and naphthalene extraction plant was installed at the Bo’ness Gas Works at a cost of £l,000. It was the second plant of the kind to be fitted in Scotland, the other installation being at St Andrews. It prevented the deposition of naphthalene in the mains and services and, in addition, the treated gas picked up any water and other impurities that lay in the services. As a result the stoppages and chokes due to water and naphthalene were no longer taking place.

This increased the capacity of the works by a quarter of a million cubic feet of gas per day, greatly improving their efficiency. The engineers were Humphreys & Glasgow of London. One unforeseen consequence was that periodically there was a loud bang when pressure was released, and this took some time for the locals to get accustomed to.

During the Second World War the Ministry of Power and Fuel oversaw the production of gas and in January 1943 the Bo’ness Gas Light Company Ltd was advised to ask for a bulk supply of gas from the Falkirk Gasworks to make up its shortfall. After the war it found that it could not get permission to renew plant at the works and in 1949 Bo’ness Gasworks became part of the nationalised industry. Gas production continued for a short time to supplement the large centres such as Falkirk, but it was not long before this was discontinued and the gasometers were incorporated into the wider distribution system.

Shortly after the aerial photograph was taken in 1967 the eastern gasometer was dismantled. The remaining gasometer was retained to assist with the national distribution of gas until 1999 when it too was demolished.

| CHAIRMAN | SECRETARY | MANAGER | |||

|---|---|---|---|---|---|

| 1844- | John Anderson, banker | 1844- | James Dunlop | Ambrose ? | |

| 1869-1897+ | William Thomson, sawmiller | 1869-1915+ | Taylor | 1869-1887 | Patrick Black |

| B1912-1922 | Ballantine,. ironfounder | 1887-1908 | John King | ||

| 1908-1918 | James Campbell | ||||

| 1922- | D.K. Harrower, Pit prop | 1910-1948 | Robert Taylor | 1918-1929 | Alexander Mackie |

| 1944 | James Moir | 1948- | J.B. Lamont | 1929- | Alexander King |

Sites and Monuments Record

| Bo’ness Gas Works | SMR 1592 |