In 1838 William Cuthill, merchant, was the first to introduce gas to Denny and supply it other people. At the beginning of that year it was merely a private concern, for his own use, but it grew in favour and the business premises of Mr Cousland, G.H. Stark, and one or two others, were soon supplied. His works were behind his house, in the back lands of Broad Street, immediately behind the engineering premises of T & J Oliphant and the tinsmith works of John Hunter & Sons.

With the increased demand Cuthill rebuilt his primitive plant on land leased from William Forbes of Callendar:

“Denny 17th May 1839

William Forbes Esqr of Callendar

Sir Having formerly spoken to you about a site for a small Manufactory for supplying the Town and neighbourhood of Denny with gas, on that part of the park held in Lease by Mr Carnie nearly opposite Thomas Clelands Smithy, I hereby beg leave to make you the following offer viz To take a Lease for the period of ninty and nine years at the rate of twelve Pounds Sterling Pr Scots acre yearly for what ground I may require for the above purpose also I wish to have liberty to myself my Heirs, Successors and assignees to occupy the said ground for building or any other purpose that may not be a nuisance to the neighbourhood or hurtfull to the running water that runs through the above park, and if you agree to the above I bind myself to pay the loss or damage of the present crop that the Lessee may sustain by my operations at the valuation of two competent judges mutually chosen, and before the above arrangement is finally ended I wish to have liberty to put down a pit or well for the purpose of ascertaining the practability of making a Tank, and if it will not suit my purpose I will pay what damage that I may do, in the same way as formerly mentioned.

If the above offer meets your approbation I shall be glad to receive an answer from you at your earliest convenience

I am Sir

Your Obedient Servant

WmCuthell” (Forbes Papers 1255/11)

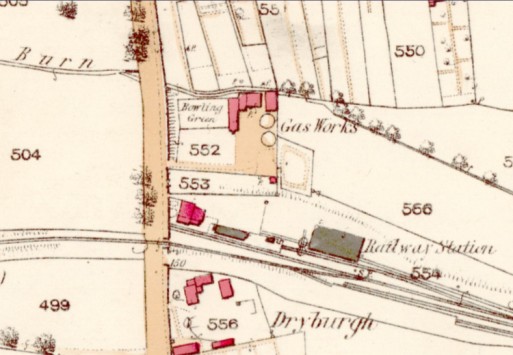

However, the second scheme of Mr Cuthill was interdicted by Mr Oliphant for spoiling his well and so a new work had to be built at a farther distance – near the later railway station behind 13-15 Glasgow Road. The gas was 14s per 1000 cubic feet and the people of Denny, believing that gas could be produced at a lower price, set about forming a joint stock gas company in 1852. The new company was the project of Thomas Leckie in conjunction with Mr Chrystal of Stirling. So Cuthill reduced his price to 12s. A public meeting was called in the Oddfellow’s Hall at which Rev R.T. Jeffrey spoke in support of the new scheme. It was agreed that the new company, to be called the Denny Joint-Stock Gas Company, should take over the works of Mr Cuthill at valuation and it proceeded in the erection of new works. Gas was then reduced from 14s to 7s, though it gradually rose somewhat thereafter.

The directors of the Denny Gas Company in 1861 were:

- John Gow, builder, chairman

- William Cuthill, merchant

- James Gow, farmer

- John Logan, flesher

- John Gray, hotel keeper

- Alexander Jack, merchant

- William Thomson, ham curer

The secretary was Mr Laing. Previous directors had included Rev Robert Thomson Jeffrey of Denny United Presbyterian Church; George Hill Stark, draper; William Gray, Inland Revenue officer; and Robert Reid, baker.

For nine years the supplying of gas to the town was in the hands of this

“snug coterie of small capitalists, who – whether it was a money-making speculation or the reverse – held the inhabitants at their mercy, whether in respect of quality or price. Complaints as to quality became deep; whilst the price was far beyond the average of the country” (Stirling Observer 3 January 1861, 4).

John Robertson, Herbertshire Street, carried on a large shoemaking business and was widely known as “Cork Robertson.” Before the penny press was in existence his workshop in Denny formed a centre where a large number of leading lights of the place assembled to enjoy the luxury of a daily paper. Local and political affairs were freely discussed. Robertson was a Radical, and indeed had been arrested by dragoons in 1820 for his support of the uprising of that year. Discontent with the quality and the high price of gas being charged by the Denny Joint-Stock Gas Company led the group under the roof of the “Cork’s” shop in 1860 to contemplate setting up a fairer gas producer and it was resolved to form a new limited liability company to be called the Denny Gas Consumer’s Company. They brought George Flintoff, the national gas reformer, to Denny and held meetings in the Oddfellows’ Hall at which Rev Falconer and Rev Cowie spoke. There then followed the Denny Gas Wars!

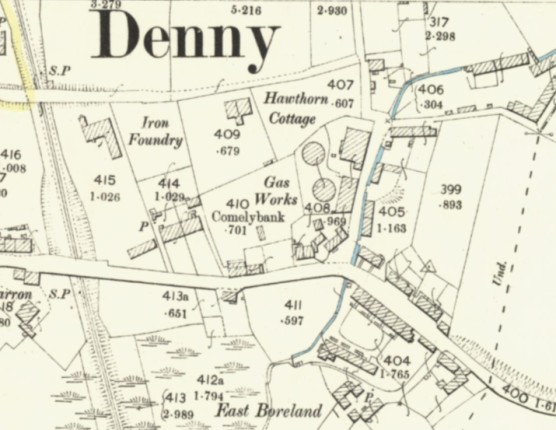

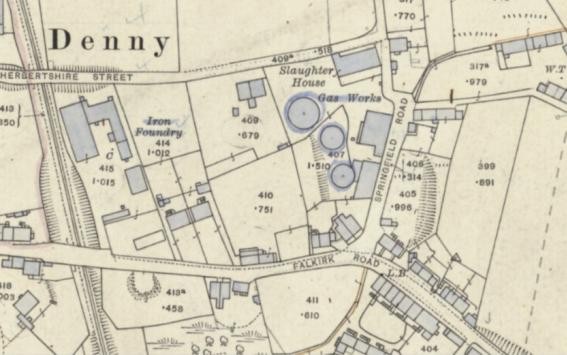

The old company had always said that it was unable to reduce the price of its gas and yet now that there was a rival on the horizon it did just that, and over the following year fetched its price down from 7s 6d to 5s 5d! During this period the Denny Gas Consumers’ Company (Ltd) acquired a site at Springfield to the east of the town and erected a new gas works, with George Fintoff as consulting engineer. To do this it had to borrow £400 from the money market – the idea was to avoid large investors insisting on high returns. The Denny Funeral Society was approached for a loan, but the directors of the old gas company exerted their influence in that society and blocked the deal. The public of Denny were indignant and fought back, the smaller members of the Funeral Society wresting back control from the few prominent ones who had wielded the power. The Denny Gas Consumers’ Company was incorporated on 7 March 1861. The start of the new gas works was delayed but it and the distribution network were in place and operational by April 1861. With interest on the loan to pay off it could not afford to sell its gas at the final reduced price of its rival and charged 5s 10d per 1,000 cubic ft. The new company had the moral backing of the community and by October that year its share of the market was greater than the old company’s. John Robertson was the first chairman and George Shand, writer, the secretary, and the first years were turbulent. Communication with the general public was well maintained and in September 1862 an extraordinary general meeting agreed to borrowing a further £600 upon the security of the works. This money was needed because the company had constructed a larger works than originally intended. To save money the annual accounts were not printed and distributed to its members; instead they could call at the works to inspect them. The interest payments were crippling, but the company did not raise its gas price. So short of money was it that George Shand handsomely made the company a present of his year’s salary as secretary in 1865 (it later turned out that he was embezzling money from his legal clients). Slowly, the company paid off its debts and turned into profit.

Then, in 1875 the Denny Joint-Stock Gas Company gave notice to the Denny Gas Consumers’ Company that it was to cease making gas after 1 June. Customers were urged to swop suppliers and the price of gas was actually reduced as a result. Ironically this took it to 7s 6d per thousand feet, the same price as the old company had been charging in 1860. However, with inflation and the increased cost of coal, this was still a good deal. One consumer wrote to the newspaper

“The old Gas Company is a thing of the past, and although some of its remains… strong-headedness and want of courtesy were the causes which led to its collapse. The new Company, with its excellent management, and under the careful supervision of Mr A R Cousland, the treasurer, and John Scott, is doing extremely well.”

In 1877 the Denny Gas Consumers’ Company (Ltd), after 16 years, was able to declare its first dividend, a modest 5%. The directors were local residents and gas consumers and so had made their investment money back in savings on lighting and fuel, though that was not exactly how capitalism was supposed to work. That November the buildings and stance of the defunct Joint Stock Gas Company’s works were exposed for sale in the Railway Hotel at the upset price of £200. After some spirited bidding it was knocked down to the railway company for £300. The pipes throughout the town were lifted by G.M. McFarlane, contractor.

John Robertson had retired as chairman in 1875 and ceased being a director three years later. In 1878 the dividend was increased to 7.5%, and then to10% the following year. It remained at that level for the remainder of the company’s existence. Robertson’s Radical approach was clearly being jettisoned.

| CHAIRMAN | |

|---|---|

| John Roberston, shoemaker | 1860-1875 |

| A.R. Cousland, merchant | 1875-1881 |

| John McQueen, agent, Clydesdale Bank | 1881-1883 |

| Thomas Shanks, ironfounder | 1883-1887 |

By 1883 the capital of the company stood at £2,500 and the price of gas was 5s 6d per 1000 feet. A small addition had been made to the works in 1882 and in 1883 £94 worth of damage was caused by a storm. Despite the low price of the gas some of the public focused on the large dividends being issued since 1879, which seemed to clash with the original principles of the company.

There had been no major investment in the works for a number of years. The erection of a steam boiler in 1884 cost £19 and the station meter which had done service since the erection of the works in 1861 being insufficient for the increasing consumption of gas was replaced in 1885 for £90. It was also necessary to replace a bench of four retorts at an estimated cost of about £50 that year. All in all the company was investing about 10% of the profits into improvements and extensions. Thomas Shanks, the chairman of the Denny Gas Consumer’s Company (Ltd), was also the provost of Denny, and in 1885 he recommended a dividend of 7.5%. This was rejected and the usual 10% (the maximum allowed under the law) was taken. However, the price of gas was reduced from 5s to 4s 7d.

The Provost’s role must have been in conflict with what happened next. In December 1885 the Denny Police Commissioners decided to use the Burgh’s Gas Supply (Scotland) Act of 1876. So, in February 1886 they sent official notification to the Gas Company of their intention to purchase the gas works. The directors of the Company agreed to treat with the Police Commissioners for the Burgh of Denny and Dunipace. The Council contracted Mr McGilchrist of Dumbarton to provide a valuation of the assets of the gas company, which he put at £5,500. This was accepted and in September formed the basis of the Council’s offer to the shareholders of the Gas Company. In October they voted to accept the offer. Meanwhile they had received another dividend of 10% and the quality of the gas produced diminished markedly. The property was transferred to the Burgh of Denny & Dunipace Commissioners of Police on 31 January 1887. At a general meeting of the shareholders of the Denny Gas Consumers’ Company on 16 September 1887, a resolution was passed to wind up the Company with the shareholders receiving the tidy sum of £2 9s 8d per £1 share.

| MANAGER | |

|---|---|

| 1887-1888 | John Potter Scott |

| 1888-1921 | John McDonald |

| 1921-1953 | Robert M. Simpson |

A Gas Committee was set up and its members became the Denny Gas Commissioners. Upon taking over, the Commissioners erected a new retort house (later used as a coal store) and installed a set of purifiers, which were dismantled in 1922 when enlarged purifiers were installed. In April 1900 the Denny Gas Commissioners accepted the offer of the Barrowfield Iron Company Ltd, Glasgow, to erect a gasometer, with a cast iron tank, of 60,000 capacity, at a cost of £3,500. The first plate was laid by Provost Ferguson assisted by ex-Provost Shanks, now convenor of the Gas Commissioners’ Committee. Provost Ferguson was presented with a silver trowel by Mr Laidlaw of the Barrowfield Company, and ex-provost Shanks received an ivory mallet from Mr McGilchrist of Dumbarton, the engineer. That December there was a terrific gale and a large number of trees were blown down; many houses had slates stripped off and windows blown in. The new gas holder, which was full of gas and in the course of being tested for opening, was swung from its position, causing the swan necks that guided the holder to slip. It was still in the contractor’s hands and a lengthy legal dispute followed.

Demand for gas continued to slowly grow. In 1904 the quantity of gas manufactured at Denny was 1.446 million cubic feet and this rose to 1.515 the following year. By 1911 it had shot up to 14 million. The new plant at Denny was now capable of producing 20 million cubic feet per annum and so was being underutilised. In May 1911 the Town Council of Denny and Dunipace received a report strongly recommending the extension of the gas undertaking to the villages of Dennyloanhead, Longcroft, and Haggs, Hollandbush and Banknock, and by seven votes to two, the Council resolved to proceed with the work. The cost involved was estimated at £3,000 and the gas mains reached Streetville just beyond Banknock by the end of the year. This had required two miles of high pressure main, a governor house at Dennyloanhead, and two miles of distributing mains. A governor house, for reducing from high pressure to low pressure, was placed at the east end of Dennyloanhead and a gas holder with a storage capacity of 50,000 cubic feet at Banknock.

By October 1913 there was an increase in consumption of 5 million cubic feet and it was still increasing, allowing the gas to be reduced by 5d per 1000 feet and further investment at the gasworks. An exhauster house was built able to handle 6,000 cubic ft per hour using Waller exhausters installed in duplicate – one set being steam driven and the other gas driven.

In 1914 a 250,000 cubic ft Livesey washer and a Holmes scrubber of the same capacity were installed, but further work had to be delayed due to the war. In 1921 Robert Simpson became the manager and produced a report advising a major overhaul. Expansion took place into the land to the south, which required the removal of 7,000 cubic yards of material from the hill there and the construction of a high retaining wall. Four purifiers 15ft square by 5ft deep, arranged in a square with a connectionless valve, were erected by Robert Dempster & Sons Ltd, Elland.

In November 1922. a two-lift spiral-guided gas-holder of 250,000 cubic ft capacity with a steel tank was placed to the north. This had first been erected for the Government by Clayton, Son & Co Ltd of Leeds at East Fortune Aerodrome during the war. It was purchased from the Government Disposal Board by the Denny and Dunipace Burgh Council and then dismantled, transported and re-erected adjoining the Denny Works by Clayton, Son & Co Ltd.

1924 saw gas supplied to Bonnybridge. A 4ins high pressure steel main was laid from the existing high-pressure main at Head of the Muir via Drove Loan to Loanfoot in Bonnybridge, where a governor house was erected to house governors supplied by Peebles & Co, Edinburgh. From the governor house an 8ins low-pressure steel main was laid to the Toll and connected there to the existing mains.

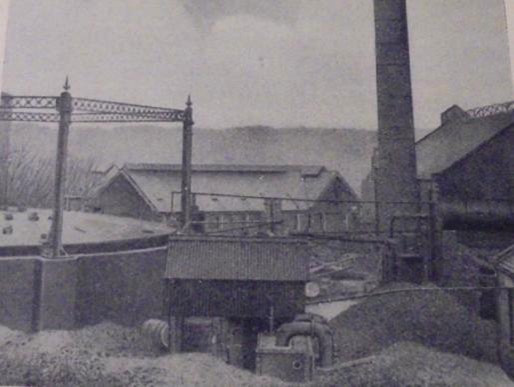

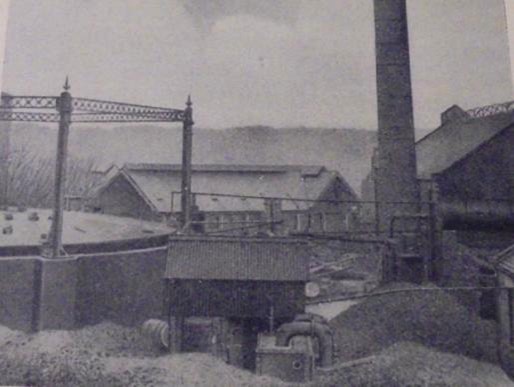

This further extension in the area supplied led to the reconstruction of the gas works at Denny. This major work included the installation of vertical Glover-West retorts, waste-heat boilers, condenser, additional compressing plant, etc, and the construction of a railway siding, tar and liquor well, coke yard, workshop, and so on. The chief schemes were submitted to the Unemployment Grants Committee, and grants-in-aid were secured, thus reducing the capital expenditure, and affording a considerable amount of work for the unemployed, both locally and in the districts of the various contractors.

.

The installation of the Glover-West vertical retorts for the continuous carbonisation of coal at the works consisted of one setting of eight retorts arranged in four sets of combustion chambers and cost about £13,000. The coal and coke-handling plant were taken well above the retort bench, so that not only could the conveyor be readily arranged to feed further retort benches in the same line, but retorts of a larger model could be installed with very little additional cost (further details can be found in a brochure produced for the opening of the new plant – see Falkirk Archives).

So, in 1933 the Denny Gas Works consisted of eight retorts with a capacity of 300,000 cubic feet per day installed in 1927; a condenser, also inaugurated from 1927 with a capacity of 750,000 cubic feet per day; the purifiers installed in 1923 and 1928 with a capacity of 500,000 cubic feet per day; a compressing plant of ample capacity by means of which the gas was forced by high pressure from the works to the supply network. The service area required 15 miles 1,733 yards of pipes, and there were two gas holders at the works – of 250,000 cubic ft and 50,000 cubic ft; one at Bonnybridge of 50,000 cubic ft; and one at Banknock of 50,000 cubic ft. The maximum daily make at the works was 256,000 cubic feet. In 1888 the output had been 6 million cubic ft; now it was 60 million. In 1922 the book value of the undertaking was £24,701, and in 1939 £87, 670.

In 1886 a new retort house had been erected, but the 1927 work made this redundant and so the building was utilised as a coal store. It was not really suited to this role and in November 1938 the gable collapsed. The building was 55ft wide and 25ft high, with walls 2ft thick. It was situated immediately to the east of the new vertical retorts and was full of 300 tons of coal nuts. Inside the building the coal was piled well up towards the roof. A local stoker, John Innes was shovelling coal into his iron wheelbarrow when he heard a rumbling sound from above. On looking up he saw the brickwork over the door beginning to give way. A moment later bricks were falling all around and the coal avalanched outwards. Innes made a dramatic dash for safety, but when almost clear he tripped and fell. Another worker came to his rescue, and he was removed from the danger zone with an injured leg.

John Innes was considered to be a lucky man. His luck ran out ten years later in March 1948 when he was on night-shift duty. He was found about 3.30am lying over the filling room door of the No. 3 producer plant. While engaged in filling coke from bags into one of the producers he had become overcome by carbon monoxide fumes and died (Falkirk Herald 31 January 1948, 2).

During the Second World War the Ministry of Fuel and Power was created which brought the gas industry into relation with the other fuel industries, coal and electricity. An overarching strategy was gradually evolved. After the war the Denny and Dunipace Gas Commissioners could finally consider the installation of an additional 3-lift gas holder at the gas works with a capacity of 500,000 cubic ft at a cost of approximately £25,000. It would take approximately two years from ordering to delivery. However, with nationalisation looming on the horizon it was a tough call. The Ministry of Fuel and Power now vetted all such work. In 1947 it refused to sanction the erection of three new vertical retorts at the Denny gas Works to cater for the increased consumption. A bulk supply from Falkirk was the official alternative suggested. The gas holder would still be required and construction work on it began in August 1948.

The Scottish Gas Board (Falkirk District), Edinburgh and South- Eastern Division, 171 High Street, Falkirk, were now responsible for gas distribution. In 1962 they admitted two contraventions of the Gas Act, 1948, in so much as on 5 October and 30 December 1961 they had allowed the gas pressure in the main gas pipe in Stirling Street, Denny, to fall below the minimum stipulated. On the first occasion workmen were making a connection in the street and turned off the wrong valve and 2000 consumers had to be informed before it could be turned on again. On the second occasion the problem was put down to freezing conditions.

In 1963 the ground at the former gas works, extending to 2.09 acres, with buildings thereon, were advertised for sale – suitable for industrial purposes. To view the site application had to be made to the Design and Construction Engineer of the Scottish Gas Board at 25 Chester Street, Edinburgh. Offers were to be made to the Secretary of the Scottish Gas Board at 26 Drumsheugh Gardens, Edinburgh. The Denny and Dunipace community was no longer involved. Finality came in 1973 when the Works chimney, one of the town’s most famous landmarks, was demolished.

Sites and Monuments Record

| Denny Gas Works | SMR 1902 | NS 8167 8287 |