Gas was introduced to Falkirk in 1829 by the Falkirk Gas Light Company (often referred to as the Falkirk Gas Works Company) formed by local businessmen and tradesmen for the purpose of lighting, in the first place, the High Street, Robert’s Wynd and Kirk Wynd. The works were constructed at an initial cost of £1,646 8s 7d and ‘lighted’ on 18 January 1830. As was usual, many consumers paid for gas on a time contract basis, but where meters were in use the charge was 12s 9d for a thousand cubic feet. From June 1831 to June 1832 the income from the sale of gas was £450 8s 10d. For the same period the expenditure was:

| Coal, lime and cartage | £102 8 8 |

| Manager | 30 0 0 |

| Sundry | 82 4 11 |

The Falkirk Gas Works Company enjoyed a monopoly and consequently the price of gas was high. Not only that but the reliability was not very good with periods of low pressure in the system making it almost unusable, and the quality also often suffered as a result of poor coal. The consumers moaned about these ills and after suffering for a long period they decided to act. At intervals of several years, various projects arose in Falkirk, having for their object the establishment of a gas company upon the joint-stock principle. On one occasion the intention was formed by a considerable section of the consumers uniting and erecting another gasworks to the north of the town. When this happened, the Falkirk Gas Works Company provided a concession on the price and so these projects were successively allowed to lapse. On each occasion the price then rose again.

Part of the problem was a lack of transparency, as one consumer put it:

“although the proprietors of the existing Work style themselves “The Falkirk Gas-Light Company,” and have issued addresses in name of their “Directors,” they possess none of the characteristics of a public company. They are a private mercantile firm. They publish no states of their affairs, but studiously conceal everything connected therewith, and this too, whilst they in effect come forward and beg the public to believe that they are actuated by motives of a public kind, and hold themselves stewards for the public good.”

By 1845 the situation had become intolerable and the public learned from their past failures.

“Profiting from the experience afforded by a knowledge of the causes which led to these results, and with the special view of guarding against any loss which might be encountered from a partial and temporary competition in price on the part of the proprietors of existing works, the Promoters of the present Undertaking resolved to proceed to carry it out only upon obtaining a written Agreement and Obligation by the general body of Consumers to take from the New Work the whole gas which they may require, irrespective of any reduction in the rate of charge which might elsewhere be made. This agreement the Consumers cordially, and all but unanimously joined in subscribing”.

As was anticipated, Falkirk Gas Works Company printed notices in the newspapers that it would make a reduction in the price of its gas. In these notices it also cautioned the public that dividing the gas production in two would increase the cost to both. It also pointed out that the annual dividend had only been in the region of 7.5%, which was not excessive. Notwithstanding this, a prospectus for the new gas company was issued, and applications for shares were received. Two of the directors of the Falkirk Gas Works Company then asked to meet with the promoters of the new works and the published points were reiterated. At the meeting it became clear that although the annual dividend over the previous six years (a period evidently selected to give the best appearance) had been reasonable, it was admitted that the alterations and extensions of the works and pipes which had been made had been paid for out of the profits, which meant that the shareholders had derived a substantial financial benefit from an increase in the capital.

The Falkirk Gas Works Company then reiterated its position in the newspapers, adding that as the existing works were sufficient there was no foreseeable requirement to spend additional sums on them and so the price of gas would probably remain low. This had the reverse effect on its consumers than it was designed to, and more signed up for the new company. The old company also printed a comparison of its charges with those of other towns in central Scotland to show that it was only the larger urban centres that were able to produce gas at a cheaper rate. This is the table which clearly shows how poorly Falkirk was actually doing:

| Per 1000 cubic feet | |

|---|---|

| Edinburgh | £0 6 9 |

| Glasgow City & suburbs | 0 6 8 |

| Stirling | 0 8 0 |

| Linlithgow | 0 8 4 |

| Kirkintilloch | 0 9 2 |

| Bo’ness | 0 8 4 |

| Alloa | 0 8 6 |

| Airdrie | 0 8 0 |

| Dunfermline | 0 7 0 |

| Bathgate | 0 9 2 |

| Falkirk | 0 9 0 |

The new company was called the Falkirk Joint Stock Gas Company and its first directors were Alex Macfarlane, Joseph Gartshore, Thomas Keir, Thomas Stark, James Rankine, James Hosie, Robert Henderson, John Jones, A Smith Jaffray. Land was acquired on the south side of the Forth and Clyde Canal to the west of Bainsford Bridge and Graham Hardie, the manager of Falkirk Iron Works, was appointed to supervise the construction work. He was also a director of the Stirlingshire Midland Junction Railway and the Alloa Bridge. The registered office of the Falkirk Joint-Stock Gas Company was at 101 High Street, Falkirk.

In order to provide Bainsford and the area to the north with gas it was necessary to lay a pipe in the bed of the canal. To have drained it for this purpose would have meant paying a large amount in compensation to the proprietors of the canal for the disruption of the commercial traffic and so they had to wait for a suitable opportunity. On 30 July 1845 Thomas Wilson, the canal’s manger, wrote and

“intimated to Mr Hardie & the New Gas Company that as the Bainsford Reach will be run dry on Friday & Saturday that they will have the priviledge to put their Gas pipes across the Canal.” (Wilson’s Log).

Not everything went so smoothly. Wilson’s entry for the 4 September reads:

“I was astonished to find that the Men employed by the New Gas Company have encroached upon the Canal Companys property in excavating for a tank to hold the Gasometer., the inside building of which is said to be 35 feet diameter and twenty feet deep and as James Hart, the Contractor for the excavation, have now commenced so that part next the Canal where I am decidedly of opinion was persisted in, will endanger the bank giving way, and thereby stop the trade of the Navigation for a considerable time, I considered it my duty to employ Russell & Aitken to take immediate steps to put a stop to such a Procedure until security was granted to Canal Company for the amount of loss which otherways they might have sustained in the avent of the South Bank happening to burst through into the Tank in Progress of being built. Ordered Russel & Aitken to write Mr Crichton on the subject.

Saturday 6th In consequence of a letter from Mr Crichton intemating a Meeting to be held at Bainsford this day at half past 12 o’clock, I went up. Met Messrs —- Engineer, Hederick, Secretary, Mr Smith, Writer on the Part of the New Gas Company, with Young & Hart, Contractors, and Mr McCall and Mr Aitken & myself on the part of the Forth & Clyde Canal Company, and after a little discussion on the dangerous state of the Bank, the Gas Company maintaining that should the bank give way all that the Canal Company can suffer is mearly the loss of water which will fill the space taken out, there being no space below the level of Canal where the water can escape, and on consideration that the longer the Interdict was allowed to remain the greater will be the danger of the Bank giving way, we agreed to lift the Interdict on condition that the gas Company was to become security for all damage the Company may sustain and to put that part of the Bank on which the encroachment was made in same state it was in previous to the operations, and pay the whole of the expense. Ordered Mr Aitken to make out an agreement to that effect previous to the interdict being lifted. Allowed Mr Hart the Contractor to proceed in mean time.”

Owing to the hurried manner in which the operation to lay the pipe under the canal had necessarily been performed, mud and water choked the pipe and when the gasworks was completed it was found to be unusable. This was a great disappointment to the Bainsford people, many of whom had got their premises fitted up with pipes in anticipation of obtaining a supply of gas. An attempt was made to rectify the fault through the aid of a diving bell, but it proved unsuccessful, the quantity of mud and earth above the pipe being such as to prevent access being got to it. William Christie, an auctioneer and one of the directors of the New Gas Company, resorted to the use of compressed air. He used a large pair of blacksmith’s double-action bellows to force air through the pipe, which successfully dislodged the sludge (Love 1910).

The two gas-producing companies were now in direct competition and the Falkirk Gas-Light Company kept its price down to 6s 6d per 1000 feet for the next six years. As a result the shareholders’ dividend fell to 5%. This was the result that the critics of the company would have welcomed before the new gas works was built, but would not have happened without that rival. However, the gas output of both companies increased substantially as a result of enlarging the area covered and due to the in adoption of gas for purposes other than lighting. In fact, the lower price encouraged consumption. Accordingly, in 1856, the two companies came to an agreement over price and continued to act as a cartel for some time – so much for the ideals originally set down by the newcomers!

“The Directors of the two GAS COMPANIES in Falkirk hereby intimate, that Gas will be supplied to private consumers during the present quarter, commencing with the month of August current, and until further notice, at a uniform rate of 7s 6d per thousand cubic feet.

A. MACFARLANE, Chairman of the Falkirk Joint-Stock Gas Company.

For the Falkirk Gas-Light Company, ROBERT HENDERSON, Secretary.”

(FH 21 August 1856, 1)

And slowly the dividends of both companies crept up. The old company announced its dividends at its annual general meetings which were held in the Red Lion Inn. The new company met on the Crown Hotel.

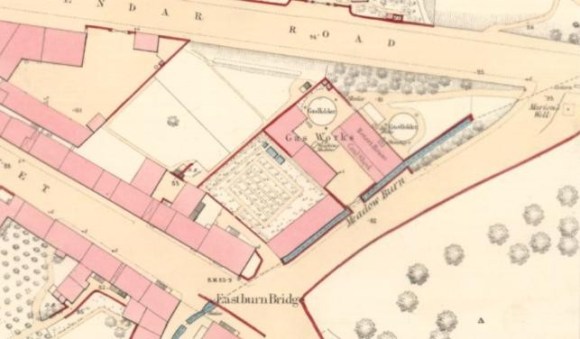

So, in 1858, when the Ordnance Surveyors were in the area, there were two gasworks, which they described thus:

“GAS WORKS A gas works situated at the south west side of Bainsford Bridge. It contains a retort house and gas holder, and is the property of the Falkirk Joint Stock Gas Company.

GAS WORKS Consists of two small gas holders and retort house & c situated at the east end of Bridge Street. The daily average consumption for the last 6 months is about 10,000 cubic feet. Rate 7/6 per thousand. The property of the Falkirk Gas Light Company.”

The gasworks in Falkirk were often at the leading edge of developments in the production of coal gas. In 1851 the works at Bainsford Bridge tested Rennie’s patent revolving cast iron retort for the inventor who lived in Gowanbank, Falkirk. The manager then wrote an endorsement of the product which pulled no punches:

“Your Patent Retort having now been in use at these works for upwards of two months, I have to report that the savings of fuel, compared with our clay retorts in use, is from 50 to 60 per cent, and from the temporary way in which it is fitted up the saving is not so great as it might be, were it in a juxtaposition to others. As far as the yield in Gas is concerned, it quite equals that from our clay retorts, while the time required for distillation is rather less. As regards the durability of the retorts (of which you are very sanguine), I can at present say nothing more than that it does not show the slightest inclination to bend. The position of the hydraulic main, placed to suit our common retorts, does not answer yours well. To those who may adopt your patent, I would say that it is necessary that the hydraulic be placed at a lower level than the retort, that the ball and socket joint may be kept as free from tar as possible – this has been a source of considerable annoyance to us, I might almost say the only one, for although the joint has leaked a little the alteration you propose will, I have no doubt, cure this.” (Falkirk Herald 5 June 1851, 1).

As well as jointly setting prices there seems to have been an unspoken agreement that the two gas companies would retain a geographic separation. The Falkirk Gas Lighting Company served Falkirk, whilst the Falkirk Joint-Stock Company served Grahamston and Bainsford, and extended to Camelon in 1858. Consequently, when, in December 1859, Falkirk Council looked for estimates for its gas lamps it wrote to each company for their “designated” areas. The inevitable result was higher gas prices. At that time only Bathgate in the Central belt had a higher price:

| DECEMBER 1859 | ||

|---|---|---|

| Linlithgow Gas-Light Co | 5s 10d | per 1000 cubic ft |

| Falkirk Joint-Stock Has-Light Co | 6s 8d | |

| Airdrie Gas-Light Co | 5s 5d | |

| Dalkeith Gas-Light Co | 5s 5d | |

| Hamilton Gas-Light Co | 5s 10d | |

| Coatbridge Gas-Light Co | 5s 10d | |

| Kirkcaldy Gas-Light Co | 5s – | |

| Bathgate Gas Light Co | 7s 6d |

From that date, however, the Falkirk Joint-Stock Gas Company took the lead in cutting the cost of gas to its customers, and was shadowed by its rival. Returns were sufficient to keep the two gasworks in good order and to extend them. In 1861 the Joint-Stock Company added a large gasometer and tank at a cost of upwards of £500. Open warfare returned in 1863 when the Falkirk Joint-Stock Company requested permission from Falkirk Town Council to provide a competitive quote for gas for the street lighting in the town. It then offered it at 3s 2d per 1000 cubic feet, undercutting the Falkirk Gas Lighting Company’s price of 3s 3½d.

In 1862 the Falkirk Joint-Stock Gas Company repeated its former practice of getting a number of signatures from potential consumers ahead of supplying them with gas, sufficient to guarantee the success of a proposed extension into Carron, Stenhousemuir and Larbert. Permission was obtained from the road trustees to break up the road for laying the pipes. The cast iron pipes were supplied by the lowest tenderer, which was George Glennie & Co of Springfield Ironworks, Glasgow. Due to the cost of extending the mains, the signatures agreed to pay a higher price for the gas for the first five years than that charged for the Falkirk consumers.

This was much the same deal that the people of Bainsford had signed up for and now they wanted the rate reduced to match that for Falkirk. The Falkirk Joint-Stock Gas Company refused. Ironically, it was now the turn of the Falkirk Gas Lighting Company to turn the tables and it received a petition from the “Cheap Gas Movement” at Bainsford in June 1863. The memorialists agreed to take gas from the rival company on similar terms and so a new pipe was led across the Forth and Clyde Canal fed by gas from East Bridge Street.

A large meeting of the gas consumers of Larbert, Stenhousemuir, Carron and vicinity, was held in the Free Church Schoolroom at Stenhousemuir in February 1865 for the purpose of adopting steps to obtain a reduction in the price of gas supplied to them by the Falkirk Joint Stock Gas Company, when it was unanimously resolved to petition the Directors for a reduction, as they considered they were paying an exorbitant price – viz, 7s 6d per thousand feet, while the same company was supplying the public in Falkirk and Grahamston at 4s 2d per thousand feet. Feelings were running strong, but it had only been three years since they had signed up and the petition was rejected. However, when the petitioners revisited the matter in 1867 it was clear that the Company was determined to continue its monopoly pricing. And so the Company which had been established to beat such behaviour in the old Company was now behaving in the same manner.

“The non-fulfilment of this promise has evoked murmurs of discontent from all quarters, as was exemplified on Saturday night week, when a public meeting of the gas consumers was held in the Free Church School-room, for the purpose of considering the best steps to be taken to procure a reduction in the price of gas.” (Falkirk Herald 3 October 1867, 2).

The Falkirk Joint-Stock gas Company merely replied that the increase in the cost of coal should have put the price up for them. That did not go down well.

“Ungrateful wretches that we are, that cannot appreciate kindness when we get it! I have heard various plans proposed to bring-down the price; some are for general giving in our meters, until such time as it will suit them to lower the price; but I see nothing to hinder us from having a gaswork of our own. I am quite sure there is no want of either capital or a suitable site if it was once set agoing. It is urged against this if we commence to erect a gasworks they would reduce the price. I have no doubt but that they would, but let the same plan be adopted that they took. Let the different districts be canvassed, and I have no doubt but that almost everyone will give their names to burn from our own gaswork on the same terms as we were bound to pay them. And I have the utmost confidence that, if a gaswork was set agoing here, we would produce gas at a much lower figure than we at present pay for it, and in course of time we might even have to cross the canal and assist them to supply the Falkirk folks…” (Falkirk Herald 31 October 1867, 2).

It was not, however, easy to break such monopolies and the problem persisted. The Falkirk Joint-Stock Company was run for the benefit of its shareholders, but the payment of dividends in excess of 7.5% looked bad in the press. The capitalists had another trick up their sleeves. In 1869 the surplus capital reached a particularly high level, and so the directors simply created additional stock which it issued to those shareholders who had paid up. This doubled their holdings and so a 5% dividend now was the same as a 10% one before – only it did not appear as such. Another ploy was to build housing for its staff. This made it easier to employ suitable people but it also increased the capital stock of the company, and hence the value of the shares, without appearing on the books.

Despite the relatively high price of the gas, demand continued to grow. The 1863 gas holder at Grahamston had to be supplemented in 1876 with another one at Bankside to hold a further 80,000 cubic feet. It was officially completed in August 1877 when Thomas Kier, the chairman of the Falkirk Joint-Stock Gas Company clinched the last rivet. The new holder was 80ft in diameter by 20ft deep, and was placed in a tank built of stone and paved with brick. A & W Black, architects, oversaw the work, and the contractors for the iron work were Hanna, Donald & Wilson, engineers, Paisley; and the mason work was undertaken by Alexander Dick, mason, Brightons.

The Falkirk Joint-Stock Gas Company was now well established, confident with surplus cash. It therefore offered to buy the Falkirk Gas Lighting Company for the sum of £7,500. Not only would this secure its monopoly, but it would also save on duplication of mains. The offer, unsurprisingly, was rejected by the shareholders of that company. They then made a counter-offer for the Falkirk Joint-Stock gas company, which was accepted by the chairman and the directors, with one exception. However, its shareholders also voted against the action. Scottish gasworks were now valued for rates based upon their profits, and hence the need to spend the surplus cash. Ironically, this led to a reduction in the price of gas, which led to an increase in consumption, which led to increased profits! The people of Stenhousemuir, Larbert and the district north of Bainsford were still paying 20% more than the residents of Falkirk.

In 1887 the amalgamation of the two Falkirk gas companies was finally agreed. The leading terms of the agreement were that the Falkirk Lighting Company sold to the Joint-Stock Company, as at 15 January 1888, the whole of the Lighting Company’s property and assets except money in the bank and in hand and book debts and accounts due. The price to be paid for the subjects was ascertained and fixed by a valuation of the property and assets of the Lighting Company made by G.R. Hislop, gas manager Paisley, and John McCrae, gas manager, Dundee. The price of the Lighting Company’s assets so fixed (except the stock of coal, coke, spare pipes and lime, which were to be paid for in cash) was paid in fully paid-up £2 shares of the Joint Stock Company on an equal footing with the shareholders of the Lighting Company. A valuation of the whole property and assets of the Joint-Stock Company was also made by the valuators already named and the amount so fixed was held to be the value of the paid-up capital belonging to the previous shareholders of Joint-Stock Company and for which they received payment in cash for coal, coke, spare pipes, and lime in stock, and fully-paid-up £2 shares of the Company as constituted at 15 January 1888, for the remainder of the total value, in lieu of the previous shares. The Joint-Stock Company, as constituted for the purposes of the amalgamation after 15 January 1888, took over the current contracts of both companies. The Lighting Company, upon the amalgamation taking place, was voluntarily wound up and the capital of the Joint-Stock Company, which retained its previous name, was increased to £40,000 in 20,000 shares of £2 each.

| 1845 | 1856 | 1859 | 1860 | 1862 | 1866 | 1869 | 1872 | 1873 | 1875 | 1880 | 1884 | 1887 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6s 6d | 7s 6d | 6s 8d | 5s 10d | 4s 2d | 5s 10d | 5s 5d | 6s 8d | 7s 6d | 6s 8d | 4s 2d | 3s 9d | 3s 2d |

The amalgamated company immediately adjusted the price of the gas to its customers. The price of gas in Larbert, Stenhousemuir, Carron, and Carronshore districts, was reduced to 3s 9d per 1000 cubic feet; and in Falkirk, Grahamston, Bainsford, and Camelon districts, it was raised to 3s 4d per 1000 cubic feet. A discount was allowed at the end of each financial year (15 May) of 5% on accounts above £20 and under £50 per annum; 7.5% on accounts between £50 and £100 per annum; and 10% on accounts above £100 per annum. The unified network of mains was reduced to 30 miles or so.

More capacity was required and so the granaries on the south side of Canal Street, adjacent to the gasworks at Bainsford Bridge were acquired, together with the quay on the canal to the west. They were then demolished and a concrete tank with a telescopic gasholder erected, measuring 92ft in diameter, 20ft 6ins deep, to hold 240,000 cubic feet of gas. The nominal capital was increased to £50,000.

The Falkirk Joint-Stock Gas Co closed off that part of Canal Street between its works and the old granary with a wooden barricade but this was torn down overnight and thrown into the canal by locals. The Company immediately re-erected it and placed a guard on the site, claiming that as the road only led to the wharf that it owned it was not a public road. It was accused of “road-grabbing” – a phenomenon of the times. The local inhabitants petitioned the Town Council to have the road opened up and, despite some of the councillors being shareholders, including the Town Clerk, it sent a letter to the Company demanding that the new barricade be removed within eight days. The secretary of the gas company replied that he would bring the matter before the first meeting of the directors. Mysteriously the next scheduled meeting was postponed. A week later ex-Provost Cockburn, chairman of the Falkirk Joint Stock Company, told the Council that they considered it as part and pertinent of their property. This belligerent attitude, with little regard for the public, was to characterise the company for the remainder of its existence.

Complaints increased concerning the gas supplied and these were put down mainly to want of pressure. Additional retorts were built and the mains replaced with larger ones as part of a rolling programme. The impurity in the gas was remedied in 1892 by additional purifiers, condensers, and an exhauster, suggested by a consultant. The price of the gas increased.

It was now clear to the company that demand for gas was going to continue to grow rapidly and that the old works were poorly located to meet this. It resolved to seek out a single larger site and build a new works. To secure the investment it decided to obtain Parliamentary powers to increase the capital, to acquire a statutory right to dig up the streets within the area that it served, and to place its monopoly on a legal footing. Several pieces of ground were investigated, including a piece of land at Woodburn, and Mr Forbes of Callendar was approached with the view to obtaining it. In the end the favoured site was at Firs where an option was taken out with the North British Railway Company for seven acres behind Wallace Street and Thornhill Road.

Notice was given to the public in November 1893 that the Bill would be put before Parliament in the 1894 session. Its sweeping powers were clearly something that Falkirk Town Council could not tolerate. Within weeks it put forward its own Bill to acquire those same powers and to buy the existing gasworks. A week later, the special committee of the Town Council which had been appointed to deal with the question of taking over the gas works had a private conference with the directors of the Falkirk Joint-Stock Gas Company on the subject. The proposals of the Town Council were laid before the directors, and after considering these, they came to the conclusion that they were not of such a nature as they could accept. There was not to be an amicable arrangement.

The following January two London gas engineers were in Falkirk at the instance of the Police Commissioners. In company with William Neilson, sanitary inspector, they went over the district and inspected the ground for the proposed new corporation gasworks. The engineers afterwards had a meeting with the Lighting Committee with the view of advising them as to what course they should adopt. The directors of the Falkirk Joint-Stock Gas Company refused to give permission to the engineers to inspect its works. This refusal was repeated in March; nor was access given to inspect the books of the Company. Amongst the organisations opposing the Falkirk Town Council Bill was the County Council.

The Gas Supply (Scotland) Act of 1876 meant that it was inevitable that Falkirk Council would get its way, but the Falkirk Joint-Stock Gas Company and its supporters ensured that it did so at as high a cost as they could. Money was wasted in trips to London, consultants, legal fees and engineers’ reports. It is hard to believe that the chairman of the gas company was an ex-provost! In July 1894 the Bill of the gas company was withdrawn and the Parliamentary Committee committed the Town Council to arbitration for the purchase of the gasworks. The gas company put its value as high as £115,000, while the Corporation as low as £33,000. That December the arbiters fixed the price at £77,050 to which sum the expenses of the arbitration had to be added and paid for by the Corporation – raising the price to around £80,000. Then the gas company took the Council to court to ensure that it was also liable for the costs of conveyancing. On 2 February 1895 Falkirk Town Council became the owner.

| FALKIRK GAS LIGHT CO. | MANAGER | |

|---|---|---|

| Thomas Baird | ||

| 1849 | John Callander | |

| Hislop | ||

| – 1861 | Hislop (brother) | Left for Coatbridge Gas Works. |

| 1861-1863 | John Young | Sub-manager. Left for Hawick Gas Works |

| Arnot | Left for Liverpool Gas Works. | |

| 1865- | David Black |

| FALKIRK JOINT-STOCK GAS CO. | MANAGER | |

|---|---|---|

| 1851 | James Erskine | |

| 1862 | Watson | |

| 1864-1865 | John Watson | Died as a result of a retort falling on him. |

| 1865 | Mr Clark | From Bailliestone. |

| 1867-1871 | Hugh Baillie | Left for works in Brazil. |

| – 1874 | James B Watson | Left for Glasgow Corporation Gas Works at Dawsholm. |

| – 1881 | Mr Fleming | |

| 1887 | Mr Watson |

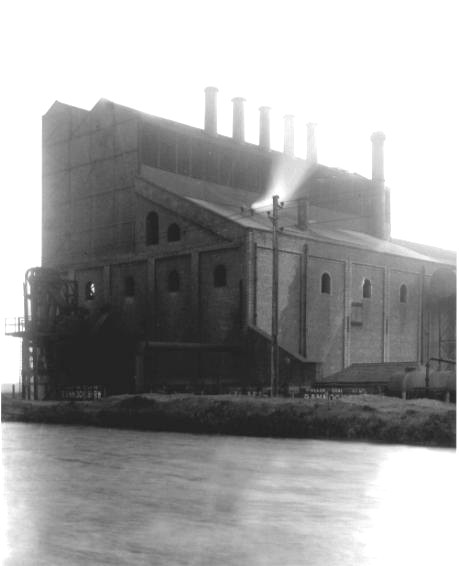

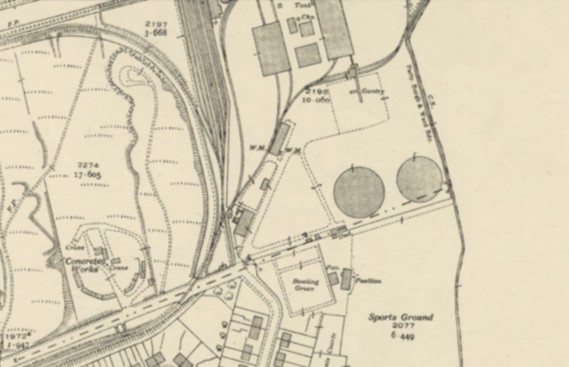

Before long the existing works were found to be inadequate for the rapidly growing requirements of the district. They were so situated as not to permit extension and had no railway communication, a matter of vital importance in undertakings of the kind. The Town Council decided to erect new gas works on a site where railway facilities would be obtained but great difficulty was experienced in determining a site. Several were considered and reported upon by gas experts and the choice ultimately came down to a site belonging to the burgh at Parkhouse or one at Thornhill. Both sites had many supporters both inside and outside the Council but after much discussion, the Council, acting on the best expert advice procurable, resolved to proceed with the erection of the new works on the 12.5 acre site at Thornhill as the ground provided a better foundation for the buildings than that at Parkhouse. Building operations were commenced at Thornhill in August 1904, using designs prepared by William MacCrae, the gas engineer and gas manager of the Town Council. The works were designed to make about one and a half million cubic feet of gas per day using a largely automated system, and the total cost was estimated at about £45,000. Negotiations with the North British Railway Company for sidings into the site had been commenced in 1903, but proved far more protracted than anticipated.

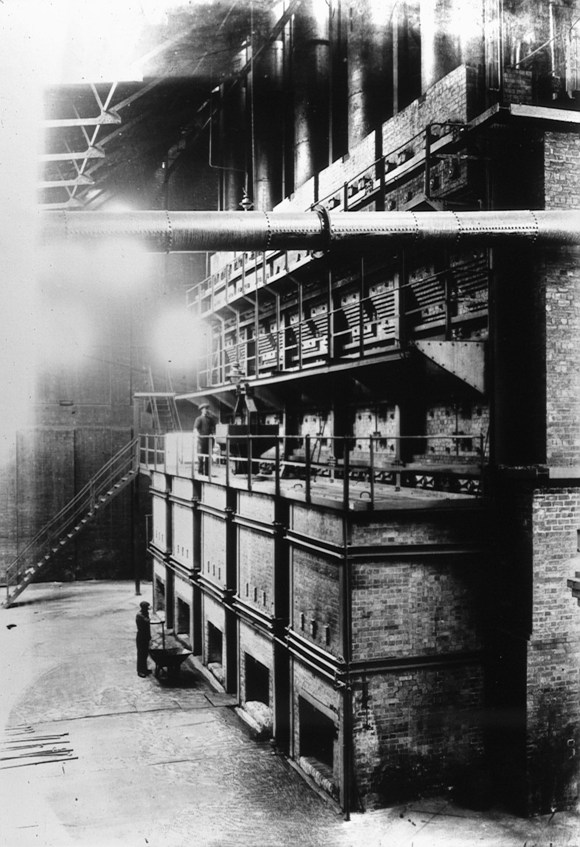

Gas was first produced at the new site in November 1905, though the official opening was 9 May 1906. The works were cutting edge with patents and improvements adopted for the first time in the country. The main buildings were the retort-house and coal store, the meter-house and exhauster room, and the purifier and lime shed – all of which buildings were constructed in a line facing the entrance from Dalderse Avenue. They were constructed of brick, with a pressed red face, by John Gardner, builder, Falkirk, and John Maxwell, builder, Falkirk. The retort-house measured 153ft in length by 70ft in width. The retort bench had accommodation for twelve ovens of eight 20ft through retorts, but initially only nine ovens were set. Horizontal through retorts were adopted, with coal charged on one side, and discharged on the other, by means machines which travelled along in front of the retorts on the charging side. The charging machine was fed with coal from two large 10-ton overhead hoppers, to which the coal was conveyed from the store and crusher by an electrically propelled elevator. The coal fell from the hopper into the weighing chamber, capable of holding from 5 to 8cwts, and was weighed. The weight of the load was registered on an indicator. The coal then passed from the weighing chamber through a telescopic shoot into the charger, which consisted of a circular box in which steel blades revolved. The coal fell against the revolving steel blades, gathering the velocity, and was thrown into the retort. The charger was driven by an electric motor of 9-horse-power, and could be raised and lowered to the three levels of the retorts, the power for this operation being supplied by another electric motor, which also worked the traversing gear. It was necessary to have the blades revolving at top speed before any coal was allowed to fall on them in order that the far end of the retort might be charged first, and by gradually reducing the speed of the motor the coal was evenly distributed along the whole length of the retorts. The charging of each retort occupied about 35 seconds. The discharging machine was of simpler design, and consisted of a ram driven by wire ropes from an electric motor. The interior of the ram was in two portions, through which water circulated for the purpose of cooling. The machine travelled in front of the retorts on the same rails as the charger, and like it, could be operated on the three levels of the retorts. The ram forced the coke out on to the other side of the retorts, and from there it fell on to a conveyor, which continually passed just below the mouth of the retorts. The machine took about 15 seconds to discharge a retort, and the return of the ram occupied another 11 seconds – the entire operation being performed in less than half a minute. The charging and discharging machines were the first two of their kind to be erected in gas works in any part of the world. The conveyor consisted of an endless chain, which carried the red-hot coke past two quenchers, which sprinkled water upon it, and subsequently the conveyor took the coke out of the works to two 25-ton and one 10-ton hoppers, underneath which was run a line of rails, where wagons were loaded with coke by opening the hoppers.

The northerly portion of the retort-house, 100ft in length by 70ft in width, was utilised as a coal store with a capacity of 3000 tons. The coal crusher was in the same building, and was capable of dealing with 35 tons of coal per hour. It could reduce the coal to any desired size, or pass it without any compressing. There were two condensers, fitted with water tubes, to cool the gas. The water for these was taken from the canal, and returned thereto after use. The boiler-house was situated behind the meter-house, and contained two boilers of the Babcock and Wilcox design of the water tube pattern, each having a heating surface of 590 square feet, and adapted to evaporate 2000 lbs of water per hour. The chimney for these boilers was 30ft high and 4ft square inside. The motor-house contained the motor and regulating bell governor, which gave the pressure of gas in the holder and the pressure throughout the town. Here too were two sets of exhausters and engines. The tar-extractor and scrubber washer were placed near the canal; the latter could treat one and a half million cubic feet per day. It extracted a portion of the ammonia, carbonic acid, and sulphuretted hydrogen.

The tar tank was built underground of concrete and measured 40ft long by 20ft broad, with a depth of 15ft, giving it a holding capacity of 80,000 gallons. In the purifier-house and lime shed were four purifiers to extract the remainder of the carbonic acid, sulphuretted hydrogen, and other sulpha compounds. The gas holder occupied the south-east corner of the ground. It had originally been erected at the Bleachfield as a two-lift holder, but was dismantled and moved and converted into a three-lift holder, raising its capacity to 750,000 cubic feet of gas.

An idea of the scale and complexity of the new works can be gained from the list of contractors:

| NAME OF CONTRACTOR | LOCATION BASED | WORK UNDERTAKEN |

|---|---|---|

| John Gardner | Falkirk | brick work of retort house, coal store, chimney, tar tank, brick work of meter and exhauster-house, messrooms, and lavatories |

| John Maxwell | Falkirk | brick work of purifier house and lime shed, boiler chimney, and boundary wall |

| Millen & Sommerville | Glasgow | iron work of retort house and coal store roof, iron work of meter and exhauster-house roof |

| Drummond & Crowe | Laurieston | slater work of retort-house and coal-store roof |

| R. Dempster & Sons, Ltd | Elland | retort bench and fittings complete, charging and discharge machinery, “Luteless” purifiers |

| Bladen & Co | Glasgow | stage floor of retort house |

| Wets Gas Improvement Co Ltd | Manchester | hot coke converter |

| Dickson & Mann | Armadale | coal handling plant |

| Ashmore Benson Pense & Co | Stockton-on-Tees | water tube condensers |

| Babcock & Wilcox | Glasgow | water tube boilers |

| R. Laidlaw & Sons Ltd | Glasgow | exhausters and engines, also station meter |

| Barrowfield Iron Works Ltd | Glasgow | iron work of purifier-house and lime shed |

| Clayton, Son & Co Ltd | Leeds | re-erection and enlarging of gas holder |

| W. & T. Avery Ltd | Waggon weighing machines | |

| James Young & Co. | Glasgow | railways inside works |

| Heron & Garrow | Falkirk | joiner work of meter and exhauster-house |

| James Milne & Son Ltd | Edinburgh | station governor |

| James Miller | Falkirk | plaster work of meter and exhauster-house |

| W.C. Holmes & Co | Huddersfield | tar extractor and scrubber washer |

| British Electric Plant Co Ltd | Alloa | electric motors |

Before long, in 1908, the retort capacity at the new gas works was increased by 50% by adding four retorts on the bench. Some 56 people were employed at the gasworks. That year it was reported that the gas mains extended to 45½ miles. The gas made amounted to 203,827,000 cubic ft. It supplied 868 public gas lamps which consumed 8,252,400 cubic ft. 160,153,600 cubic ft of the gas went to private consumers and the remainder to industry. The price charged was 2s 9d per 1000 ft and Larbert now paid the same price as Falkirk. Considerable extensions and improvements were made to the gasworks.

On 8 December 1912 a condenser used for cooling manufactured gas was not working properly and so William Wilson, the works manager, was engaged for several hours trying to put the appliance right. He had just left the condenser when a loud explosion took place. Portions of the metal of the condenser were sent in all directions. Wilson had a narrow escape and, fortunately, no one else was injured. The damage amounted to over £700, which was insured. Wilson was the first gas manager in Scotland to institute the extraction of toluol and benzol for the manufacture of explosives. From early in 1915 he acted as the district supervisor for the Ministry of Munitions in the extraction of these by-products.

After the First World War, in 1920-21, vertical retorts were erected at a cost of around £63,000, and further vertical retorts were added in 1934-35. By then the mains had been extended to 62 miles, and the pipes ranged from 24ins to 3ins in diameter. During the previous year 5,389 tons of smokeless fuel, 383,235 gallons of tar, and approximately 300 tons of sulphate of ammonia, were produced and sold. This involved the carbonisation of 20,918 tons of coal, which yielded 19,621 cubic feet of gas per ton. There were then 13.047 domestic consumers. The growth in consumption can be roughly tabulated as:

- 1896 – 78 million

- 1900 – 114 million

- 1906 – 178 million

- 1910 – 196 million

- 1916 – 232 million

- 1920 – 223 million

- 1926 – 309 million

- 1934 – 410 million

- 1930 – 360 million

- 1940 – 442 million

- 1950 – 789 million

- 1960 – 1,039.6 million

In 1934 no rents were charged on meters, and consumers of the Falkirk gas were provided with a cooker or range-plate on free loan. The Gas Department showroom in Glebe Street also had high-class cookers for hire or hire-purchase. The future of the Falkirk Gas Department looked bright and in 1938 it contributed to the Gas Pavilion at the Empire Exhibition in Bellahouston Park.

1938 also saw the erection of a new showroom at the corner of Falkirk High Street and Buchanan Court. Designed by Copland and Blakey, architects, Falkirk, it was a handsome two-storey reinforced-concrete structure typical of the 1930s. The large showroom windows slanted inwards towards the main entrance.

They were bordered in bronze, and above them and running almost the full length of the building, was bronze lettering on a black marble background. Above this imposing frontage, and set back a little so as to provide a balcony, was the upper storey structure, which housed a lecture hall. Floodlights on the balcony were intended to show off the modernity of the building, but it opened on 18 September 1939 under blackout conditions. The lecture room was useful in demonstrating how to cook with the food rations.

During the war the Ministry of Fuel and Power was established to co-ordinate energy supplies. Priority was given to war industries and private consumers were asked to reduce their consumption by a quarter. This led to the centralisation of production and paved the path to nationalisation after peace returned. Shortage of equipment led the Bo’ness Gas Light Company Ltd to ask for a bulk supply of gas from the Falkirk Gasworks in January 1943. Shortage of fit manual labourers in October 1944 led to the employment of Polish soldiers as stokers. These men had been directed to the works by the Ministry of Fuel and Power, with the cooperation of the Ministry of Labour. They had been more or less been kicked out of the Polish Army because they were Jews!

In October 1946 Falkirk was given the go ahead to order new purification plant at a cost of around £27,320 from Henry Balfour & Co. Ltd., Leven. At the same time the gasworks at Grangemouth was refused governmental permission to extend and upgrade and so it too was forced to ask Falkirk for a gas supply. Falkirk was amongst the many local authorities to oppose the scheme to nationalise the gas industry, but realised it was inevitable. Its price offer to Grangemouth therefore took into account the cost of the new pipeline along the towpath of the Forth and Clyde Canal to the Grangemouth gasworks. Normally this would have been recouped over a long time period, but now it had to be done over a shorter term. In December 1946 Polmont also heard that the Secretary of State for Scotland had refused permission for the works there to be upgraded.

On 1 May 1949 all the property of the Falkirk Gas Department was vested in the Scottish Gas Board. In 1952 it was announced that Falkirk was to become the generating centre for a coal gas “grid” to serve the needs of East Stirlingshire as well as parts of West Lothian. The Falkirk District of the South-Eastern Division of the Scottish Gas Board was granted permission to proceed with the extension of the retort house, including the coal and coke handling plant, at the Falkirk Gasworks.

The estimated cost of the first-phase development was given as £173,800, with a 20 years plan to cost over £325,000. Falkirk was to employ the same number of men as before, but the conditions for them would be better as manual handling would be minimised. Before long Linlithgow reported a marked improvement in the service that it was receiving.

The further development of the grid system and the availability of supplies from the Lurgi plant in Fife meant the closing of the works at Falkirk in 1963 and the site became a regional depot. Rationalisation in 1994 reduced the number of such depots and it too closed, followed a few years later by the gas showroom on the High Street.

| DATES | MANAGER | NOTES |

|---|---|---|

| -1903 | Kincaid | Moved to Dundee Gasworks. |

| 1903-1907 | William McCrae | Died within a month of resigning. |

| 1907-1918 | William Wilson | From Kirkintilloch Gasworks. Left for Burton-on Trent Gasworks. |

| 1918-1919 | George P Mitchell | Left for Blackburn Corporation Gasworks. |

| 1920-1945 | H.G. Ritchie | 1920-1945 |

| 1946-1949 | Ewing |