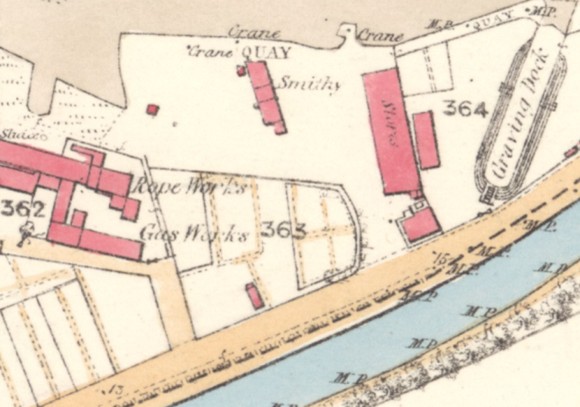

At the beginning of the nineteenth century Grangemouth was still a brash new town, quick to adopt the trappings of urban centres. There is a suggestion that in the early nineteenth century William Murdoch, whose pioneer work in street lighting by gas is well known, studied the area as a possible source of marsh gas for lighting purposes (Third Statistical Account of Grangemouth), but this is pure speculation. In the 1830s one of the leading citizens, John Mackay, was asked to raise a company for the lighting of the town. On 29 September 1834 he and a group of prominent gentlemen from the fledgling town met in the Globe Inn in Canal Street and agreed to set up the Grangemouth Gas Company. A contract of co-partnery was drawn up (copy in Falkirk Archives a684.10) and the capital was set at £1,000 in £10 shares. They wrote to Lord Dundas asking for his support, suggesting that he buy shares in the company, and asking for a site for the gasworks. He agreed to lease a piece of ground 70ft square in Milne’s Park and here the company erected two cast iron retorts at a cost of around £400. The works were located at the south end of South Charlotte Street near Welch’s shipbuilding yard on the north side of the Grange Burn – probably re-using an old whale oil boiling house. David Arnot of Falkirk was contracted to lay the pipes and erect the street lamps. At first, nothing larger that a 4ins pipe was laid down. It commenced production of gas in 1836, with the streets lighted by gas for the first time on 19 June. The directors were James Adamson (shipbuilder), David Robertson (merchant), James Brooks (merchant), Peter Wilkie (wright) Thomas Simpson (baker), John Miller (painter), David Graham (grocer) George Waddell (tide surveyor) – all residing in Grangemouth. At the helm were John Wyse (treasurer), John S Mackay, George G Mackay, Archibald Gault, Henry Stark (chairman). The first manager was Peter Watson, followed by John Young. By the end of the decade the annual revenue was about £300.

In 1843 the Junction Lock was constructed just to the south of the gasworks. It connected a timber basin in the west to the new wet dock and deliberately skirted the south side of the town. The following years were not always easy for the gas company. On the morning of Monday the 22nd December 1845, while William Sym, manager of the gasworks, was in the act of examining the purifier, an explosion of gas took place, lifting the roof off the building. He was hit on the head by the falling debris. After lingering in much agony till Tuesday morning, he died (Stirling Observer 25 December 1845, 1). Thomas Wilson, the supervisor of the eastern end of the Forth and Clyde Canal, mentions this incident in his diary.

Ten years later, on 14 August 1855, the gasworks appear once again in Wilson’s log:

“The Directors considered that would [be] attended with much less expence to take the ground occupied as Gardens and the gas work [to] widen the Junction Cut to the extent required so as to form a Basin to accommodate the Steam vessels which will be required as a greater number is expected to the Port. This suggestion appeared to be the unanimous opinion of the Directors and agreed as the first preliminary step to advise his Lordship on the business and ascertain upon what condition the ground can be got.”

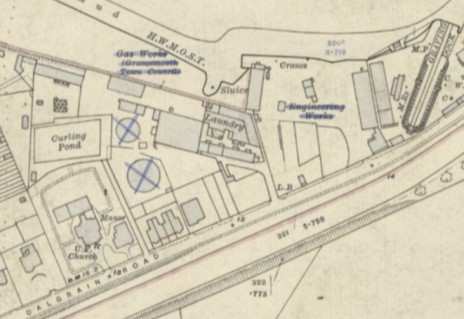

And that is what happened. The Gas Company received notice to quit as the ground was required for the enlarging of the Junction Lock. It was offered a feu in the Cowpark adjoining the Free Church off Dalgrain Road. Construction of the new gaswork was undertaken in 1857, at the same time as that on the adjoining ropeworks of James Stark & Sons, which had also been displaced by the work on the Junction Dock. The new gasworks started producing gas the following year.

“FOR SALE BY PRIVATE BARGAIN, THE REMAINING MATERIALS of the GRANGEMOUTH OLD GAS WORK. Offers to be received Henry Stark till o’clock on Monday, 5th proximo. The materials must be removed without delay. Grangemouth, 29th Sept., 1857” (Falkirk Herald 1 October 1857, 1)

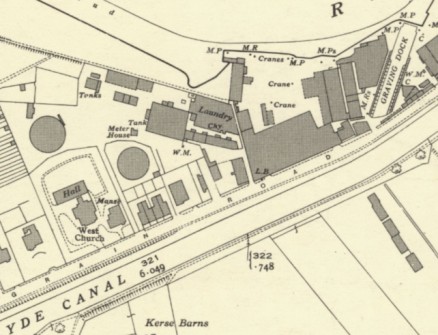

The 1860 Ordnance Survey map shows no gas-holder at the Grangemouth Gasworks and so it seems to have been 1874 before one was erected:

“CONTRACTS FOR GASHOLDER AND GASHOLDER TANK. The Directors of the GRANGEMOUTH GAS COMPANY are prepared to receive OFFERS for a 60′ x 14′ GASHOLDER with all Connections, and for the CONSTRUCTION of a BRICK TANK for same at their works here. Plans and specifications may be seen with the Manager, and Offers received by the Secretary...” (North British Daily Mail 30 April 1874, 1).

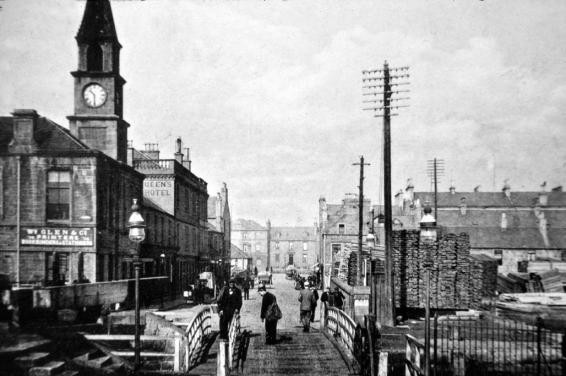

In 1885 discussions were held within the Grangemouth Commissioners as to the possibility of taking over the gasworks and a special committee was set up. This matter was to rumble on for another two decades. In 1890 the Grangemouth Gas Company was reconstituted as a limited liability company with a capital of £10,000 in £10 shares. The works were extended the following year. The company felt a public obligation to promote the welfare of the town and up until 1893 it supplied gas free to the Public Institute for the lighting of the clock at its building in South Bridge Street.

This was worth £8 a year. That year the Town Council took over the building and the gas company agreed to continue its contribution.

The town was rapidly expanding to the east. This provided new consumers and in 1898 a second gas-holder was constructed. Like other gas producers, Grangemouth Gas Company arranged cookery demonstrations and the lease of cooker and heating appliances to increase demand. In June 1904 an exhibition was held in the town hall. In the following year Grangemouth Town Council decided to invoke the Supply Act of 1876 to press for the takeover of the gasworks. The Council reflected on how this had been achieved in Falkirk and decided that a private Parliamentary Bill was not for it, preferring the compulsory arbitration laid out on the 1876 Act. In the meantime it re-opened negotiations with the gas company and arranged for a valuation from Mr Gilchrist of Dumbarton. That came in at £24,000 but, as it omitted certain items, an offer of £25,000 was made. The gas company, however, fixed its price at £33,000, and eventually they settled on £28,500 without arbitration. The business and assets were transferred to Grangemouth Town Council on 16 May 1906.

The gasworks struggled to break even during the First World War. The years after the war were not much better and owing to a large deficit of £8000 in the three years up to 1922 the Grangemouth Gas Commissioners increased the price of gas by 10d per 1000 cubic feet and proposed an additional charge of 6d as a gas contingent rate. A large part of the problem was due to the increased price of coal as a result of a series of miners’ strikes. The old inefficient plant did not help. After two years the debt was paid off and the gas price was reduced, temporarily.

When Provost Murray was made chairman of the Gas Commissioners in 1926 he did a tour of inspection :-

“My first visit to the gas works was an oppressive and disheartening experience. From the horizontal retorts a considerable wastage of leaking gas was apparent, and everywhere coal tar dripped from the ironwork. The stokers, sweating and grimy, went about their unviable tasks mostly enveloped in clouds of dust and steam. Periodically high tides caused flooding within the works, threatening to extinguish the furnaces and making gas-making conditions appalling…”

It was decided to erect eight new retorts and renew sixteen at a cost of around £1,200 in order to cope with the demand for gas in the burgh and increase efficiency. This would give a total of six benches of eight retorts each; each retort was equal to one million cubic ft of gas per annum, so they would be able to supply 48 million cubic ft. Estimates from R & G Hislop for the renewal of the two benches came in at £234 10s each; and for the construction of a new bench of eight retorts £561 exclusive of brick work and mountings, which would add £50 and £300 respectively. Second-hand mountings would cost only £100 (from a works where they were being displaced by vertical retorts). It was agreed to accept Hislop’s offer for the renewal of two benches – one that financial year and the other the next year, and to erect a new bench using the second-hand mountings.

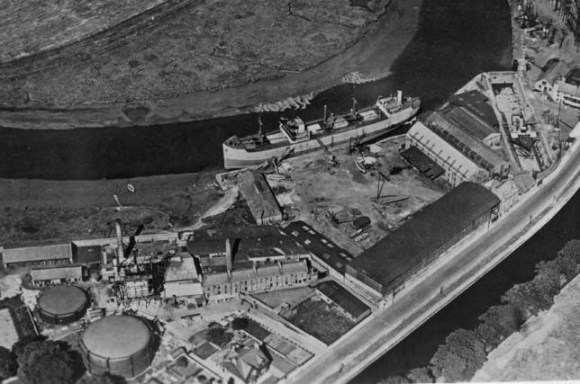

Part of problem that the gasworks was now experiencing was a huge rise in demand from industry. On one day in March 1926 Scottish Dye Works was taking a third of the total production. Grangemouth was a boom town and a massive number of new homes were being built – and these used gas for cooking. As an interim measure, the gas was enriched with oil to make it go further. This resulted in increased fumes and the laundry adjacent to the gasworks, belonging to Turnbull & Murray, was unable to work when there was a westerly wind and the Tully plant was in operation.

.

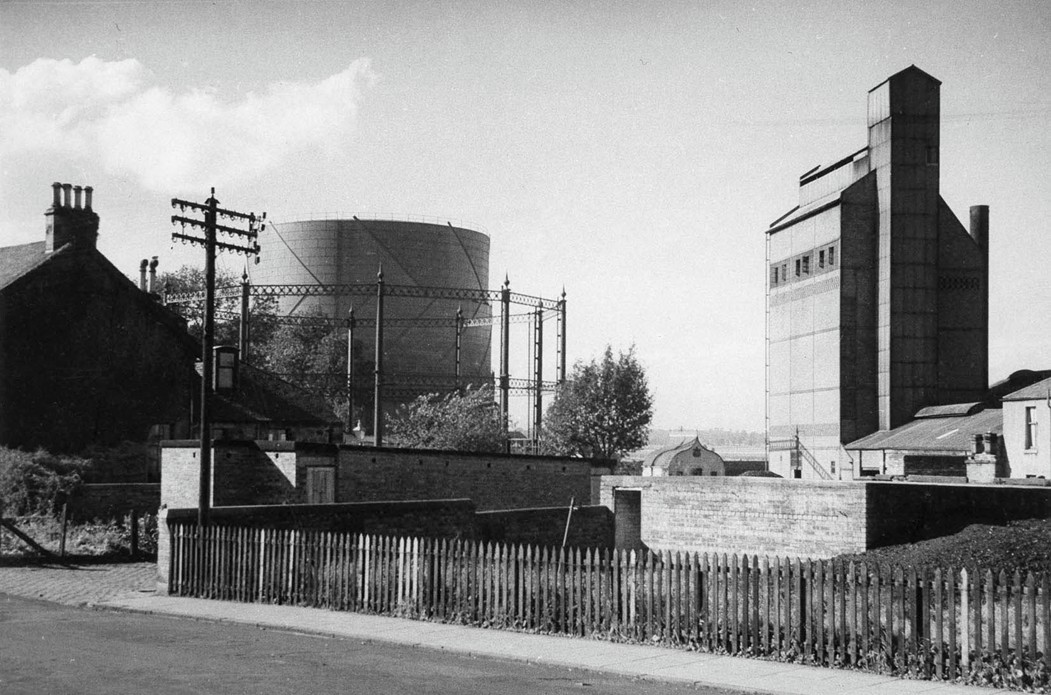

All of these measures were seen as sticking plaster and in 1930 a large programme of extension was undertaken. The new installation consisted of five large Glover-West vertical retorts arranged in single line so that each retort was an entirely independent unit, being separately heated and controlled. Coal was brought from store in side-tipping bogies and elevated to the overhead bunkers in a 25cwt electric lift.

Driving test piles proved that the ground was unsuitable for piling and so the foundation for the new building took the form of a special reinforced concrete double raft. New steaming, condensing, washing, and scrubbing plant supplied by Henry Balfour & Co, Leven, were also added.

The total cost was £14,500, though a substantial grant for employment was received. In 1907 the annual output had been 31 million cubic ft, and in 1931 it was 65 million. The vertical retorts performed very well and this resulted in a large reduction in the price of the gas charged to the public.

Sales of gas increased from 1926 to 1936 by 60%, and so new ground was bought in 1933 and the gasworks was extended. A second large gas-holder was erected in 1938 to ensure the gas pressure. In 1941 a further scheme of extensions began and that year new purifiers were installed. A carburetted water gas plant, capable of manufacturing 250,000 cubic feet of gas daily quickly followed. By 1944 the sales of gas were 150% up on the 1926 level. The price of gas was then 6d less than in 1926, yet the price of coal had almost doubled. The gasworks, from which 125 million cubic feet of gas were sent out in 1944, were valued at over £75,000. 7,500 tons of coal were used.

Despite the enlargement of Grangemouth Gasworks, the plant reached the limits of its capacity early in 1947. T.A. Rowan, the gas manager, appealed to house holders to economise – reversing decades of practice. An extension to the gasworks at a cost of £35,000 had been recommended, but the Ministry of Fuel and Power withheld permission and suggested that Grangemouth should obtain a bulk supply from Falkirk. This ran counter to the intuition of the Grangemouth councillors, but in March 1947 Grangemouth Town Council had to agree to pay an annual sum of £1,025 to meet the expenditure involved in laying a 12ins high-pressure main from the Falkirk gas undertaking along the Forth and Clyde Canal to the Council’s gas holder at Grangemouth. The estimated capital cost, including all auxiliary equipment, was £10,000 and a 25-year loan was arranged.

The creation of this medium-distance grid was one step on the road to nationalisation, which occurred in 1948. In 1961 work began on a pipeline as part of the Scottish Gas Board’s £1,250,000 scheme for conveying petroleum gas from the Grangemouth Refinery to Granton Gasworks to improve regional supplies. A catalytic reforming plant and a compressing plant were installed at Granton to process the refinery gas so that it could be mixed with the coal gas supply. The Grangemouth gas was carried east through 21 miles of 16ins diameter pipeline for mixture and distribution. A further 23 miles of pipeline were then laid between Granton, Armadale, and Falkirk, to link up with the super grid.

In 1935 the Calor Gas Company was established to distribute bottled butane and propane, which were produced at oil refineries and Grangemouth became a major supplier.

| DATE | MANAGER | NOTES |

|---|---|---|

| 1836 | Peter Watson | |

| -1845 | William Sym | |

| -1861 | John Peter Young | Went to Falkirk Gas Co |

| Robert Young | Brother | |

| 1866-1902 | Alexander Winton | Noted engineer of early cars |

| 1902 – | Charles Winton | Son |

| 1920-1922 | Lawrence Farquhar | Promoted from assistant manager, Alloa |

| 1922-1927 | Hamilton F. McNair | From Tayport Gasworks |

| 1927-1935 | Arthur Cuthbert | Moved to Stirling Gas Light Co |

| 1935-1949 | Thomas A Rowan | From Thurso Gas Light Co; appointed by the Scottish Gas Board to be district manager of the Vale of Leven District |

| DATE | CHAIRMAN | NOTES |

|---|---|---|

| 1834-1836 (?) | John Mackay | Banker |

| -1856 | John Wyse | |

| 1856-1906 | Henry Stark | Ropemaker |

| 1872 | 1873 | 1878 | 1879 | 1882 | 1883 | 1890 | 1892 | 1894 | 1896 | 1897 | 1900 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (A) | 6s – | 8s 6d | 5s 10d | 5s – | 4s 7d | 4s 2d | 3s 9d | 4s 2d | 3s 9d | 3s 9d | 3s 6d | 4s 2d |

| 1901 | 1904 | 1913 | 1916 | 1919 | 1921 | 1922 | 1928 | 1931 | 1935 | 1937 | 1939 | 1943 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (A) | 3s 9d | 3s 4d | 2s 10d | 5s 5d | 5s 10d | 5s – | 5s 6d | 5s | 4s 2d | 3s 9d | 3s 4d | 4s 2d | 4s 7d |

| (B) | 3s 4d | 5s 10d | 6s 5d | 5s 5d | 5s 5d | 4s 7d | 3s 6d | 4s 4d | 4s 11d |